. Precision meets innovation: SensoTech is shaping the future of process analysis SensoTech is setting new standards in the world of industrial fluid analysis. With high-precision measurement technology and innovative […]

. Precision meets innovation: SensoTech is shaping the future of process analysis SensoTech is setting new standards in the world of industrial fluid analysis. With high-precision measurement technology and innovative […]

SensoTech presents the latest webinar series on the impact of innovative inline monitoring on safety and efficiency in the production and application of sulfuric acid. From November 14 to 16, […]

Phase separation is a fundamental process in various industries where a product passes into two or more separate phases, each of which has different physical or chemical properties. A fast […]

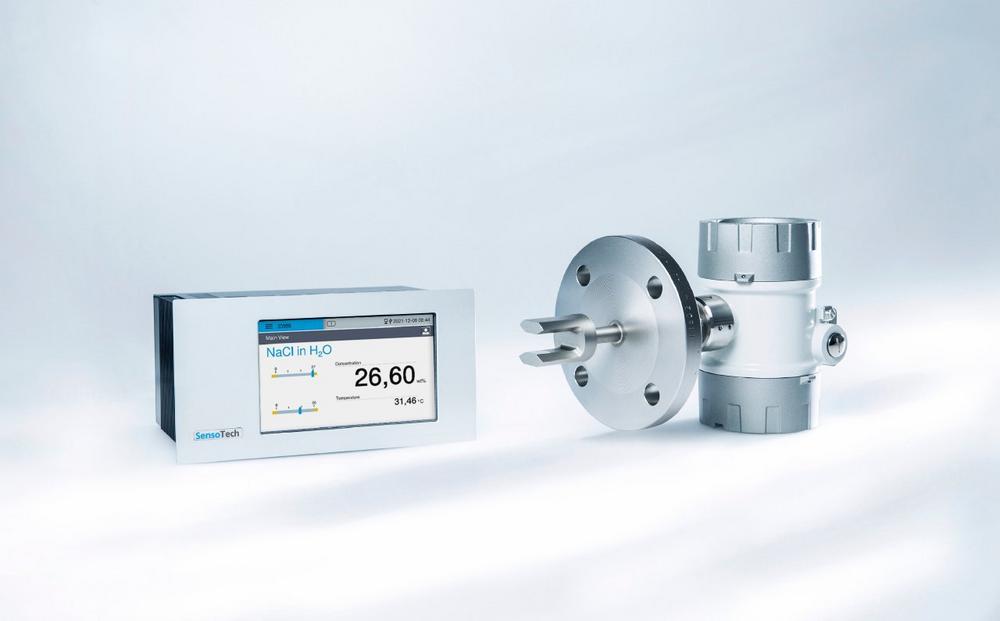

Chlorine and caustic soda are essential chemicals whose production is indispensable for downstream chemical processes. Due to the immense production volumes, small deviations and errors in the individual production steps […]

Determining the oil content in the refrigerant circuit often brings challenges for users. Sampling is difficult due to the high pressure in the circuit. In addition, the refrigerant evaporates as […]

Decades of experience show that measurements, especially in the refrigerant circuit, are costly and complicated in research as well as in test centers. Sampling is often difficult or not feasible. […]

Environmentally harmful, corrosive or toxic gases are used in a large number of industrial processes. To protect people and the environment, the treatment of these gases is subject to strict […]

Conventional monitoring of sulfuric acid and oleum is carried out in many production facilities with manual sampling. These samples are then analyzed in the laboratory and a result is available […]