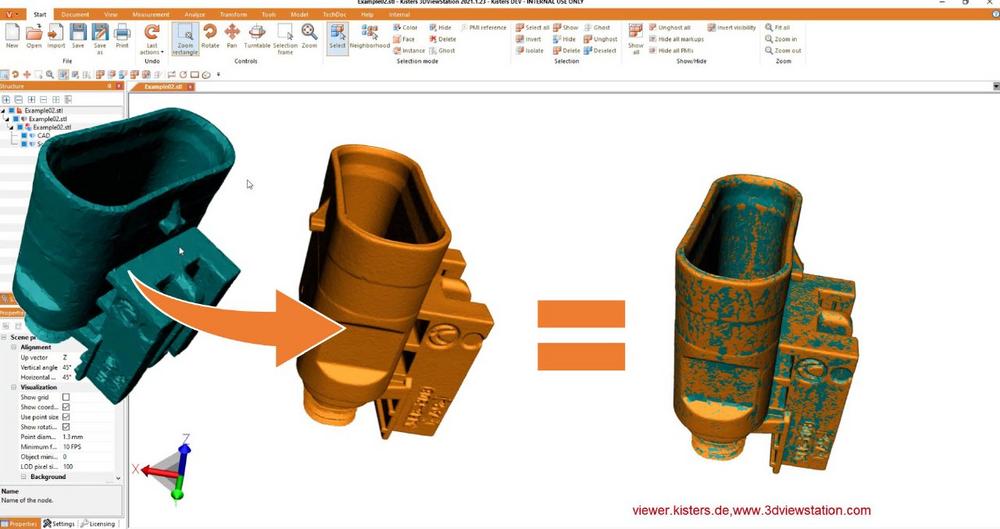

The 3DViewStation now compares a 3D scan with the original CAD data set with the usual strong performance. According to Jim Eardly, U.S. Sales Director for KISTERS, a point cloud previously acquired by a 3D laser scanner must be correctly positioned on top of the original file. “What used to be a challenge is a breeze now,” he said. “Using a special algorithm, the 3DViewStation iteratively finds the best possible alignment. Quickly and automatically at the push of a button, despite huge amounts of data.”

A target/actual comparison shows the problems visually, which pure data sets can only convey with difficulty, Eardly explained. “Some application examples for the comparison include proof of correct initial sampling, analysis of shrinkage and warpage behavior, or as an aid for tool correction of injection molds, die casting molds and casting molds,” he said. The rich features of KISTERS 3DViewStation are already well received by over 2,000 companies and bring competitive advantages not only in quotation costing or manufacturing, but also in quality assurance.

With the analysis results of the KISTERS3DViewStation, costs can be reduced, workflows simplified and product and process quality increased. Delays in production and part release as well as quality costs are significantly reduced and the return on investment is realized after a very short time.

Known for its modern user-interface, high performance viewing, advanced analysis and integration capabilities into leading systems, 3DViewStation ships with current and mature importers for a broad range of 3D and 2D formats including Catia, NX, Creo, SolidWorks, SolidEdge, Inventor, Revit, JT, 3D-PDF, STEP, DWG, DXF, DWF, MS Office and many more.

The latest developments of 3DViewStation can be reviewed in more detail at:

https://www.3dviewstation.com/news/blog.html

According to Eardly, KISTERS 3DViewStation is continuously enhanced in response to customer needs and requirements. It is available as Desktop, VR-Edition and HTML5 WebViewer product versions plus the online collaboration tool VisShare. All product flavors are intended to be used together with a PLM, ERP or other management system product configuration or service and spare part applications, providing all necessary APIs. For cloud, portal and web solutions, there is an HTML5-based WebViewer solution available, which does not require client installation. All file formats can be used in combination with the intelligent navigation and hyperlinking features to address the needs of complex integration scenarios.

With more than 25 years of success in the market as a provider of superior visualization solutions from desktop to mobile, KISTERS has become one of the top players in the visualization industry. The company’s clients range from small firms to well-known multinationals, comprising more than 3,000 customers and over 200,000 installations worldwide. The 3DViewStation’s easy-to-use interface is suitable for all user groups and 100% customizable to everyone’s specific requirements. In addition, KISTERS offers expert advice and support in concept development based on client requirements.

KISTERS AG

Pascalstraße 8 + 10

52076 Aachen

Telefon: +49 (2408) 9385-0

Telefax: +49 (2408) 9385-555

http://www.kisters.de

2D/3D Viewer

Telefon: +49 (2408) 9385-171

Fax: +49 (2408) 9385-555

E-Mail: Germar.Nikol@kisters.de

![]()