GELITA used their collective scientific studies of functional proteins to develop NOVOTEC® CL800. Proteins are a key performance factor in complex biological systems like the human body where functional proteins lubricate joints, stabilize bones and protect the skin. Transferring this knowledge to industrial and, specifically, metalworking applications, GELITA’s protein-based additives combine industry efficiency advantages with health and environmental friendliness in MWFs.

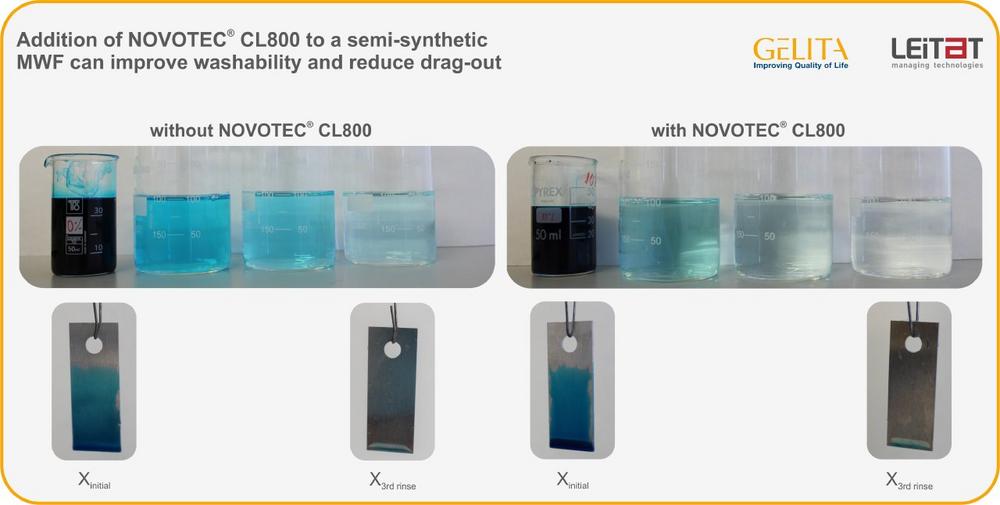

The innovative function of the new additive NOVOTEC® CL800 results in its ability to protect metal surfaces with a hydrophilic protein layer, which repels oil-based components of water-miscible MWFs without negative influence on lubrication performance. Thus, facilitating cleaning of machines, tools, and workpieces from oil and smut.

Users of MWFs with the additive NOVOTEC® CL800 are rewarded with less cleaning downtime – up to a half-day per week! There is less grit and thus reduced abrasiveness, higher quality parts and longer tool life. There is also less excess MWF on chips, translating to reduced drag out, and lower consumption rates.

A trial conducted from August 2019 to March 2020, compared two synthetic MWFs with and without NOVOTEC® CL800. During the head-to-head trial, a U.S. automotive parts producer, used MWFs customized with NOVOTEC® CL800 and provided by Diversified Chemical Technologies: Unicool 388G and Unicool 397G. After less than two weeks, reduced foaming and smut reduction were visibile and resulted in machines and workpieces being significantly cleaner. Part quality was improved while lowering labor costs and reducing health and environmental impacts.

Using an MWF with NOVOTEC® CL800 means processed parts can be ready faster for downstream processing steps such as bonding, welding, painting, or coating; without the need for more intensive cleaning. Customer experiences show that the consumption of MWFs with the additive NOVOTEC® CL800 can be reduced by up to 40% due to better cooling, wetting behavior, and less drag out. Metal chips can be collected and re-processed with less focus on removing residual oils: reducing costs, decreasing labor, and increasing production efficiency.

Foaming, is another crucial topic for MWF users. Foam, comprised primarily of air, cools poorly. So, the fact that NOVOTEC® CL800 reduces foaming, is relevant for lower temperatures and better lubrication resulting in higher quality parts and longer tool life. Moreover, NOVOTEC® CL800 is not based on silicon as are the majority of defoamers; clearly, a plus when the surface needs to be cleaned for coatings later on.

User safety and well-being is also of paramount importance; whether in the form of air quality, reduced oil-contaminated waste, or skin protection. Additionally, skin contact often results in irritation or a more severe allergic reaction due to the surfactants needed to stabilize the oil in the emulsion. NOVOTEC® CL800 is a skin-friendly, natural product with very low allergenic potential.

Industry is a cut-throat world. In most industrial sectors, businesses are challenged to improve productivity and efficiencies and reduce costs – all while being friendly to the environment and operators alike. Industries centering on metal fabrication and machining, can have an edge over their competitors simply by using a customized solution for their MWFs with the additive NOVOTEC® CL800.

Bottom line: NOVOTEC® CL800 will improve yours! Less foaming, cleaner machines, and workplaces mean better parts at lower cost, while reducing health and environmental impacts. Essentially, NOVOTEC® CL800 offers a better return on investment for industry, for operators, and the environment.

Contact GELITA for help in formulating a true cutting-edge solution for your MWFs.

Visit us at www.gelita.com

GELITA is the leading company for manufacturing and marketing collagen proteins. Coordinated from the headquarters in Eberbach, Germany, GELITA provides customers around the world with products of the highest standard, comprehensive technical expertise and sophisticated solutions. More than 20 sites and a global expert network ensure that state-of-the-art know-how is always available for customers. With 140 years of experience in the field of collagen proteins are the basis of GELITA’s performance. A strong requirement for innovation is the driving force of the family-owned company that is always looking for new solutions for food, pharmaceutical, health & nutrition as well as for technical applications.

Within the range of collagen proteins, GELITA supplies collagen peptides with proven body-stimulating capabilities, tailor-made gelatines and non- or partly- water soluble collagens. This holistic range of products in combination with its vast experience in developing solutions for different applications makes GELITA first choice for its customers. In today’s landscape of highest consumer demands, manufacturers of food products have to rely on natural, healthy, non-allergenic ingredients for their developments. Collagen proteins from GELITA are the perfect match for this as they fulfill all of these requirements, a particular plus being the fact that they are foodstuffs in their own right (e.g. no E-number). They also possess a set of unique technical and physiological properties.

Besides the traditional use of collagen proteins as natural stabilizers and emulsifiers for countless products, they enable manufacturers to provide their products with other properties which are becoming more and more important. GELITA has intensified its research in developing solutions for physical mobility, weight management and beauty from within.

GELITA AG

Uferstr. 7

69412 Eberbach

Telefon: +49 (6271) 8401

Telefax: +49 (6271) 842701

http://www.gelita.com/

ANM Communications

Telefon: +1 (312) 617-6248

E-Mail: amy.maggio@anmhealthcare.com

Marketing Coordinator North America

Telefon: +1 402-429-2130

E-Mail: angie.rimel@gelita.com

![]()