“I am very glad to see the innovation of ASM at the exhibition. The new solution of smart factory is refreshing. My personal favorite is the automatic material logistics solution supported by AIV.” In the new normal during and after the pandemic, ASM can consistently provide strong technical and service support for electronics manufacturers, which provides a strong guarantee for them to resume production, continue to develop, and further enter the smart factory. ASM, with its leading technology and process quality in the placement machine and printing machine industry, helped OPPO to develop the advanced concept of smart factory as early as the end of 2017. “At present, the first stage of integration and testing has been successfully completed.

With the continuous implementation and introduction of ASM integrated smart factory scheme in OPPO, the two sides will also carry out more extensive and in-depth cooperation in production automation, process optimization and other aspects” says Mr. He Aiting, Senior Manager, Guangdong OPPO Mobile Telecommunications Co., Ltd.

Live: Automated material logistics and setup changeovers

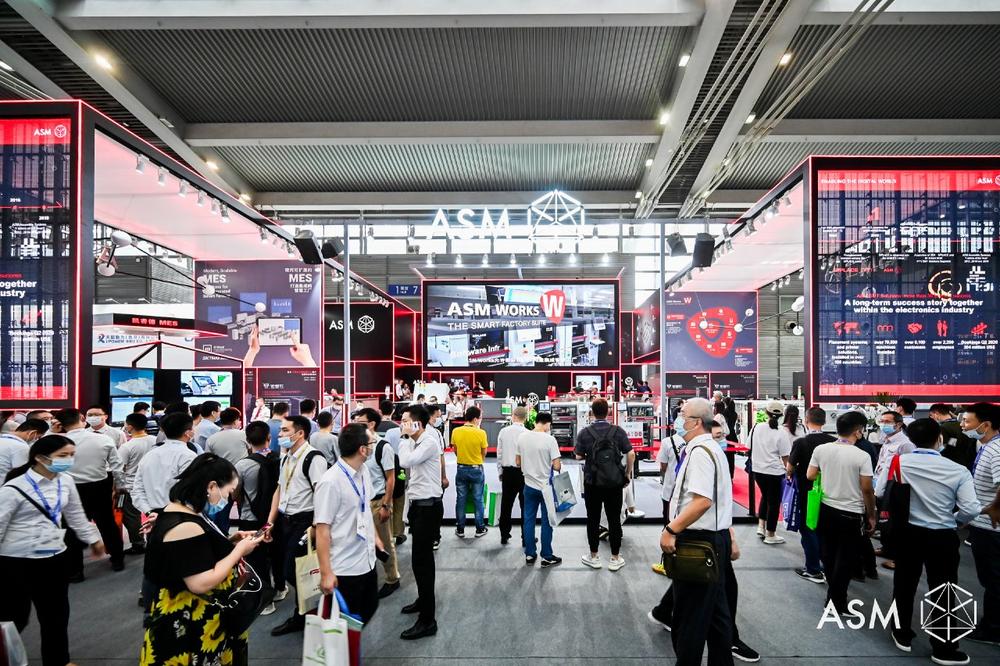

The Integrated Smart Factory area showed a successful integration example. ASM and Hikrobot jointly demonstrated the AIV automatic material logistics and line changeover solutions. Through the AIV, it can accurately connect with SMT placement equipment to realize the automatic material setup from the material preparation area to the production line, which was controlled with software from the portfolio of ASM Factory Solutions. No manual intervention is needed in the whole process. The new ASM AutoRefill Feeder, whose ability to automatically insert two component tape reels simplifies refills and reduces their frequency, plays a special role in these demonstrations. At present, the automatic material logistics showed in the booth has been successfully tried out in the ASM SMT CoCs in China, and interested parties are welcome to make an appointment.

"The introduction of AIV into production has the advantages of flexible deployment, rapid expansion, high positioning accuracy, safety and reliability. This is also one of the processes with which ASM helps electronic manufacturers to realize their smart factory. At the same time, even existing customers can benefit from improved quality, capacity and flexibility due to the continuous upgrading and transformation of ASM solutions. This makes ASM a strong partner for customers looking to transform their productions into integrated smart factories. " says Herbert Hofmann, Vice President and Managing Director of ASM`s Greater China SMT Solutions Segment.

The SMT Solutions segment of ASM Pacific Technology

The mission of the SMT Solutions segment within the AMS Pacific Technology Group (ASMPT) is to implement and support the smart SMT factory at electronics manufacturers worldwide.

ASM solutions such as SIPLACE placement systems and DEK printing systems support the networking, automation and optimization of central workflows with hardware, software and services that enable electronics manufacturers to transition to the smart SMT factory in stages and enjoy dramatic improvements in productivity, flexibility and quality.

Since maintaining close relationships with customers and partners is a central component of ASM’s strategy, the company has established the SMT Smart Network as a global forum for the active exchange of information between and with smart champions. In addition to being a founding member of the ADAMOS joint venture for the development of an IIoT platform for manufacturing companies, ASM is establishing together with other SMT manufacturers the open HERMES standard as a successor to the SMEMA standard for M2M communication in SMT lines.

For more information about ASM visit www.asm-smt.com.

ASM Pacific Technology Limited

Headquartered in Singapore, ASMPT (HKEX stock code: 0522) is a global technology and market leader in leading-edge solutions and materials for the semiconductor assembly and packaging industries. Its surface mount technology solutions are deployed in a wide range of end-user markets including electronics, mobile communications, automotive, industrial, and LED. The company’s continuous investments in research and development help to provide its customers with innovative and cost-efficient solutions and systems that enable them to achieve higher productivity, greater reliability and enhanced quality.

For more information about ASMPT visit www.asmpacific.com.

ASMPT GmbH & Co. KG

Rupert-Mayer-Straße 48

81379 München

Telefon: +49 89 20800-26439

http://smt.asmpt.com

HighTech communications GmbH

Telefon: +49 (89) 500778-10

E-Mail: b.ostermeier@htcm.de

Marketing / Communication Global

Telefon: +49 (89) 20800-26439

E-Mail: susanne.oswald@asmpt.com

![]()