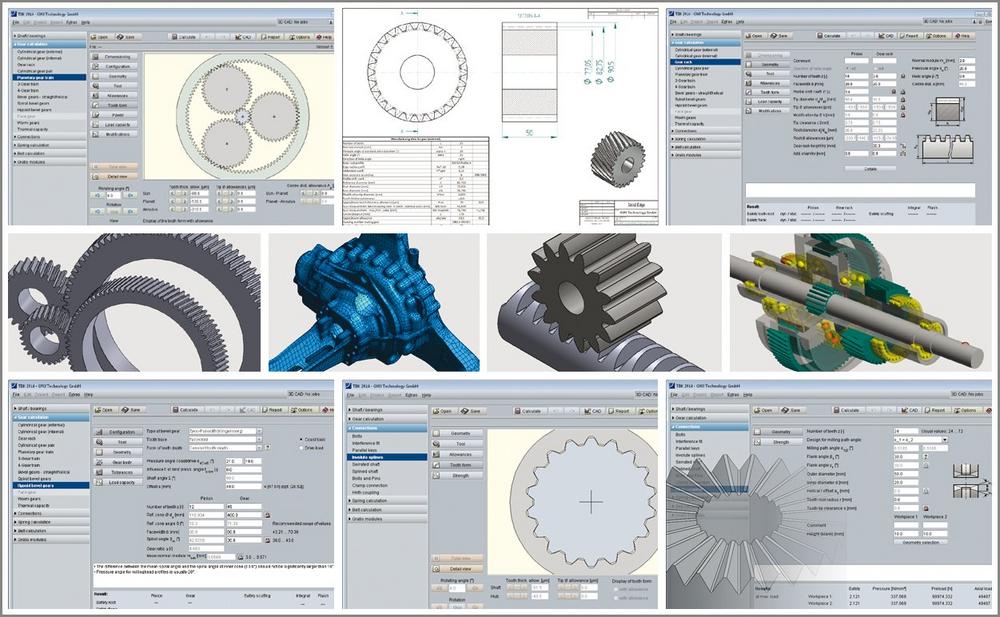

In the latest version, the load capacity calculation according to DIN 3990 and ISO 6336 has been revised and expanded in the calculation modules for cylindrical gear pairs, planetary gear trains, 3- and 4-gear train systems and gear racks. It is now possible to individually specify additional factors such as the roughness and lubricant factor as well as the velocity or size factor. Furthermore, the calculation in the fatigue strength range has been improved.

In addition, a detailed verification of the load capacity calculation according to ISO 6336:2019 was carried out using the eight practical examples from ISO/TR 6336-30 published in December 2022. The comparative calculations performed provide very good correlation with the examples from ISO/TR 6336-30. In all eight examples, the absolute deviation of the calculated safeties is ≤ 0.01. These results once again show the high quality of the TBK calculation modules.

Furthermore, the wear resistance according to VDI 2736 for dry-running plastic gears was added to the cylindrical gear pair, gear rack and gear train system modules.

In response to many user requests, the old DIN 3967 from 1953 for gear tolerances and tooth width dimensions, which has been withdrawn for many years, has been integrated into the calculation modules for single cylindrical gears, cylindrical gear pairs, planetary gear trains, gear train systems and gear racks. The number of decimal places for the input fields can now also be configured individually in these modules.

For the design layout available in the cylindrical gear pair and planetary stage modules, additional options have been implemented for the variant calculation, such as “Allow specific sliding > 3” or “Allow small geometry errors”. The result variants can now also be exported in CSV format.

In addition to the splines according to DIN 5480, ISO 4156, ANSI B92.1 (imperial version), ANSI B92.2 (metric version) and DIN 5482, the French standard NF E 22-141 from 1955 is now also supported in the involute spline module. In doing so, the Primary Series was included as the recommended preferred series of NF E 22-141 for flank-centered splined shaft connections with a flat bottom with the associated tool reference profiles and tolerances.

The calculation of hypoid bevel gears, i.e. bevel gear pairs with offset, is now possible with a new calculation module.

In addition to the new TBK version, new versions of the CAD plugins for SOLIDWORKS, Solid Edge and Autodesk Inventor are available. Besides the additional generation of 3D rotation surfaces for tip, pitch and root circles, these offer completely new and extensive options for the automatic generation of tables with the gear data on manufacturing drawings.

Visit www.gwj.de for more information or contact GWJ at +49 (0) 5311293990 or send an email to info@gwj.de.

Focusing on mechanical engineering, GWJ Technology stands for high-quality products and professional software development for mechanical engineering to support engineers and designers in their daily work.

The GWJ product range of innovative calculation software is wide – from standard software for classical machine elements with 3D CAD integration modules to the determination of whole systems up to a complex special software for 5-axis milling of gears.

There are common features that all GWJ solutions share – intuitive design, sleek interface, easy to use and suitable applications for all users from beginner to very advanced. GWJ is constantly working on software enhancements and adding new features to the system in order to keep the applications up-to-date.

Professional competence, state-of-the-art technology, a demand for high quality and excellent customer services are the key factors in GWJ´s business philosophy to give the customers the best possible service and advice to obtain new competitive advantages.

GWJ Technology GmbH

Celler Straße 67 – 69

38114 Braunschweig

Telefon: +49 (531) 129399-0

Telefax: +49 (531) 129399-29

http://www.gwj.de

Geschäftsführer

Telefon: +49 (531) 1293990

Fax: +49 (531) 12939929

E-Mail: g.weser@gwj.de

Technische Dokumentation

Telefon: +49 531 1293990

Fax: +49 531 12939929

E-Mail: s.sack@gwj.de

![]()