In many plastics processing methods such as extrusion, injection moulding or blow moulding, flow properties play a key role in optimizing these processes and ensuring efficient and error-free production. Rheological measurements make it possible to characterize and evaluate the flow properties of materials under various conditions such as temperature, pressure or shear. Process parameters such as temperature profiles, speeds and cooling rates can be controlled more precisely by understanding the rheological behavior.

Rheological measurements are essential for successful product development

Rheological measurements are also used in industry to monitor the consistency of material batches, classify materials for specific applications and carry out quality controls. They make it possible to characterize the viscoelastic properties of new materials, assess their suitability for certain applications and provide valuable information on the flow and deformation properties of plastics. They are therefore indispensable for efficient production, high material quality and successful product development.

Introduction to dynamic mechanical analysis

At the SKZ Plastics Centre, a new two-day practical seminar will address the importance of the rheological behaviour of plastics and their metrological characterization. The seminar is aimed at experts from the plastics industry who would like to deepen their knowledge in the field of rheology and the associated measurement technology and will take place for the first time on December 4 and 5, 2024 at the SKZ headquarters in Würzburg. The first day of the seminar includes in-depth lectures on the fundamentals of plastics and rheology and an introduction to dynamic mechanical analysis before participants work on their first case studies.

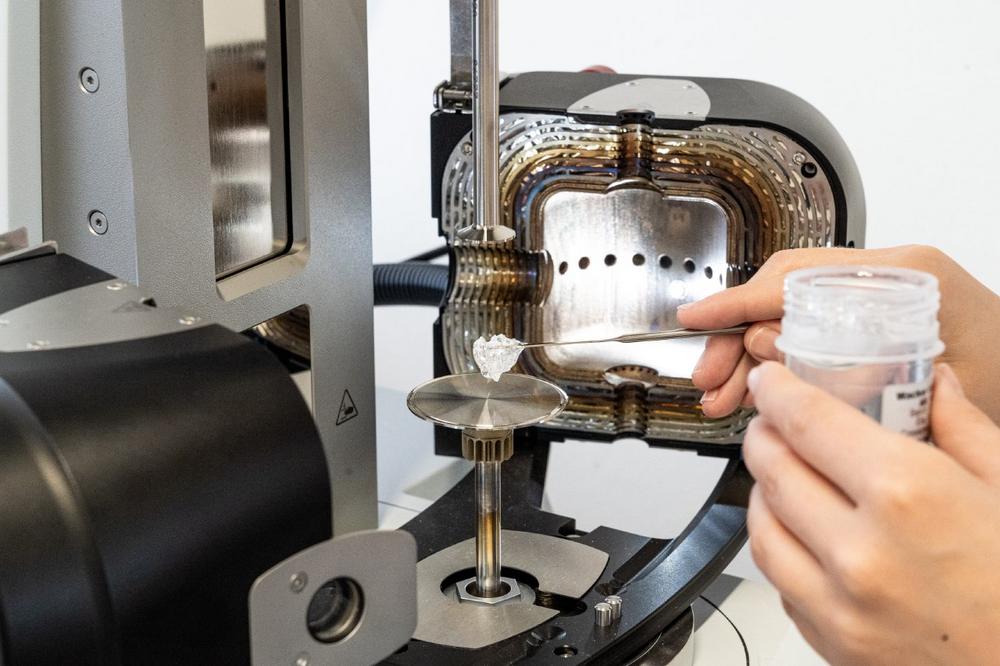

Practical exercises on modern equipment

In order to optimally prepare participants for the challenges they will face in practice, the seminar offers theoretical lectures as well as practical exercises on modern measuring equipment. In small groups, case studies will be carried out on several rotational rheometers, a dynamic mechanical analyzer (DMA) and a high-pressure capillary rheometer (HKR) in order to apply the knowledge gained directly. A joint Franconian dinner will give participants the opportunity to exchange ideas with each other and the speakers in a relaxed atmosphere.

Industry experts from the sector

“The aim of the seminar is to generate a deeper understanding of the metrological characterization of rheological properties and, above all, to transfer this into practice,” says Alina Heihoff, scientist and course leader at SKZ in Würzburg. “I am particularly pleased that we were able to win Anton Paar Germany GmbH as a cooperation partner for the seminar. This means that additional measuring equipment will be made available for the practical exercises so that participants can work in small groups. In addition to other speakers, e.g. from Göttfert Werkstoff-Prüfmaschinen GmbH, we have industry experts on site for the presentations and for the technical management of the case studies.”

The SKZ is climate protection company and a member of the Zuse Association. This is an association of independent, industry-related research institutions that pursue the goal of improving the performance and competitiveness of industry, especially SMEs, through innovation and networking.

FSKZ e. V.

Friedrich-Bergius-Ring 22

97076 Würzburg

Telefon: +49 931 4104-0

https://www.skz.de

Scientist | Bonding and Surface Engineering Würzburg

Telefon: +49 (931) 4104-682

E-Mail: a.heihoff@skz.de

Presse- und Öffentlichkeitsarbeit

Telefon: +49 931 4104-197

E-Mail: p.lehnfeld@skz.de

![]()