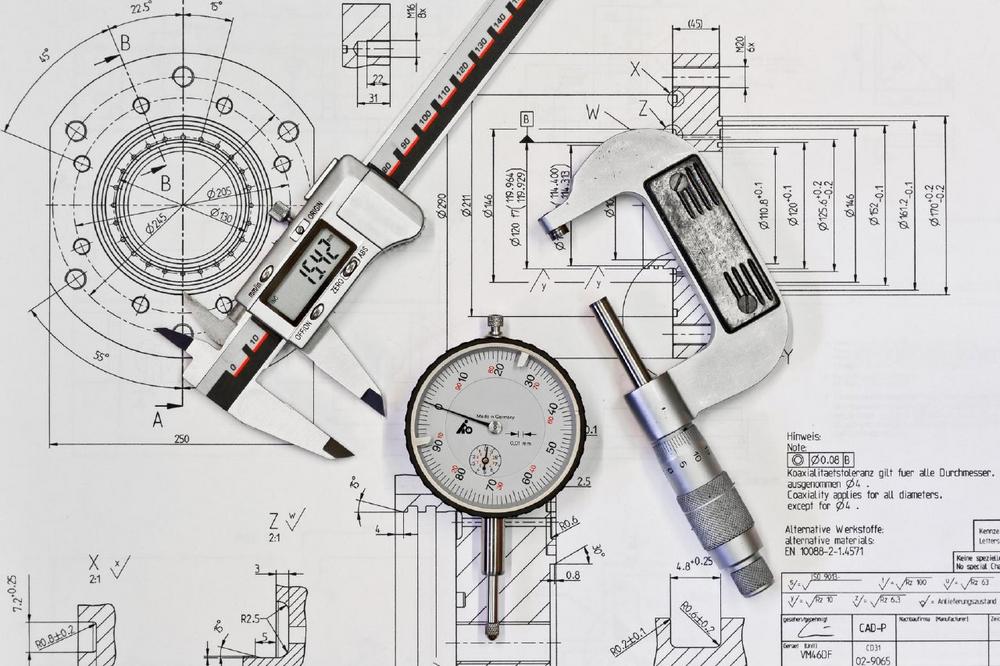

In addition to the actual development of plastic products, the tolerancing of these products is an essential skill for product developers. The ability to read drawings correctly and to assess the information provided in terms of its significance and manufacturability is crucial. The basics are defined in industry standards, but the exact design is a question of specialist knowledge and experience. The aim of the general tolerancing of plastic molded parts is to enable a discussion at eye level between all project participants. The discontinuation of DIN 16901 has created a vacuum with regard to meaningful general tolerancing, which has led to the development of various in-house standards. These have often shifted responsibility to tool and mold makers and parts manufacturers.

SKZ closes the gap in demand

This affects specialists who define tolerances for OEMs, for example, whereby tolerances are often defined very narrowly due to a lack of experience. At the same time, specialists in parts design at suppliers need the knowledge to correctly interpret the tolerance specifications and take measures with regard to production. The fact that not everyone involved in the project is familiar with the contents of standard-compliant tolerancing often leads to major misunderstandings along the value chain. The SKZ would now like to close this gap in demand and has designed a course on the tolerancing of plastic components. In order to make it as easy as possible for as many companies as possible to participate in this knowledge transfer, the course will be offered on several dates at the SKZ locations in Halle a.d.S., Horb a.N., Peine and Selb.

Evaluating tolerances sensibly

In terms of content, tolerancing using general tolerances (ISO 20457) and the basics of form and position tolerancing (ISO 1101) are on the agenda. In addition, participants will be equipped with technical arguments for discussions with toolmakers, product developers and end users. This will enable the various parties in the supply chain to evaluate tolerances sensibly and design plastic parts in such a way that both functionality and an efficient production process are guaranteed.

Lack of knowledge of tolerancing principles

“Recently, we have observed that misunderstandings regarding the tolerancing of plastic parts in the industry are increasingly consuming money and time. Ultimately, however, many problems are simply due to a lack of knowledge of tolerancing principles,” says Ruben Schlutter, Group Manager Component Properties at SKZ. “In this course, we want to convey practical, simple recommendations for action and make access as easy as possible for companies, which is why we offer the course on various dates throughout Germany and are also happy to conduct it in-house.”

The SKZ is climate protection company and a member of the Zuse Association. This is an association of independent, industry-related research institutions that pursue the goal of improving the performance and competitiveness of industry, especially SMEs, through innovation and networking.

FSKZ e. V.

Friedrich-Bergius-Ring 22

97076 Würzburg

Telefon: +49 931 4104-0

https://www.skz.de

Group Manager | Component Properties

Telefon: +49 (931) 4104-4060

E-Mail: r.schlutter@skz.de

![]()