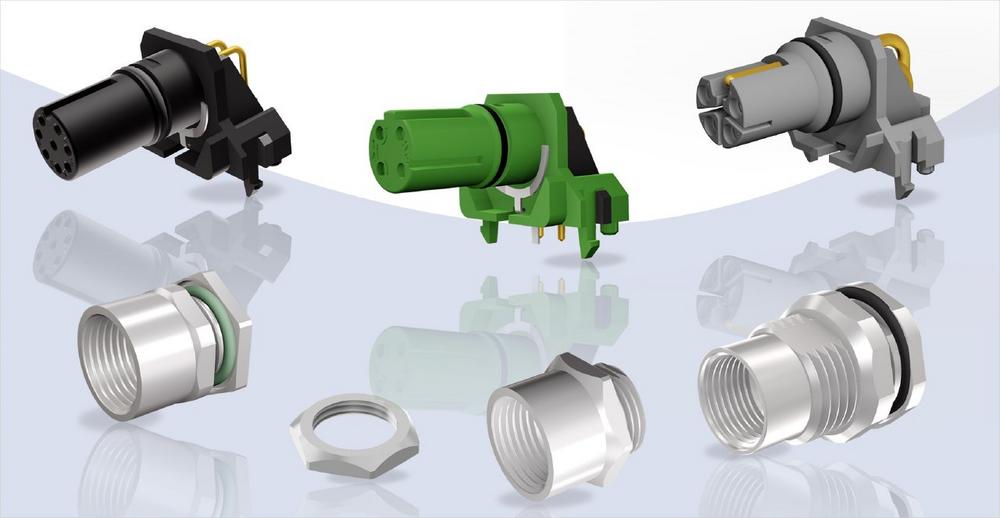

For use in these application cases CONEC offers M12x1 PCB sockets two-part with an O-ring integrated on the insulation body.

Due to the O-ring, the socket connectors are sealed against moisture from outside, even when unplugged. The two-part circuit board sockets are available with A-coding 4-, 5-, 8- and 12-pos. as well as D-coded 4-pos. for front and back panel mounting. The L-coded version is available for back panel mounting with 4- and 4+FE pos.

The user can mount the board equipped with the insulating body in various socket geometries. The CONEC sockets are suitable for combined mounting and are ideal for a design where the M12x1 thread of the socket is directly formed. This creates maximum design flexibility.

The insulation body fitted with angled contacts is snapped into the circuit board and then processed in a wave solder bath or by selective soldering. The connector housing is screwed into the device and the circuit board with the contact insert is mounted to it. The spring-loaded shield plate contacts the connector housing and ensures the shield connection.

In the installed state and locked with the counterpart, protection class IP67 is achieved. The connectors are suitable for housing wall thicknesses of 2-3 mm and for PCB thicknesses of 1.6 mm.

The angled connector design makes it possible to position the PCB horizontally in the device, which in turn facilitates the assembly.

The innovative M12x1 flanges meet the special requirements of the market because of the following properties:

• Two-part (separation of insulating body and socket housing)

• Modular assembly

• O-ring on insulating body

• Suitable for front and back panel mounting (L-coding only back panel mounting)

• Suitable for fast data transmission (M12x1 D coding)

• For high current load capacity up to 16 A (M12x1 L-coding)

Advantages:

- Large tolerance compensation between board and socket

- Suitable for various socket geometries

- Low load forces for the circuit board

- Low contact resistances of the shielding

- May also be used without CONEC socket housing

Fields of application:

- Drive technology

- Automation technology

- Housing and device production

- Assembly and production lines

- Servo motors

- Process control

For more than 40 years, CONEC Elektronische Bauelemente GmbH has been developing, producing and marketing high-quality connectors, patch cable and single ended cable as well as enclosure technology.

CONEC products are used in automation, telecommunications and energy technology, machine manufacturing, agriculture and medical technology, transportation and the aviation industry.

The headquarters in Lippstadt has a large research and development department, its own tool-making department, a CNC-turning department and a synthetics injection moulding plant.

As part of the Amphenol Group, CONEC participates in the growth and development opportunities of a globally active group and at the same time acts flexibly and quickly as a medium-sized company in order to optimally adapt to changing customer needs.

In addition to a variety of connectors for all current standards, our particular strength is the integrated moulding of components and assemblies and the development of customized solutions.

CONEC is a global player with its own subsidiaries and/or production sites in Canada, China, the Czech Reblublic, Poland, Slovakia and Mexico.

The product portfolio includes connectors of the following categories:

• D-SUB/IP67 D-SUB Connectors

• IP67 RJ45 / USB / Mini USB / Fiber Optic LC Duplex

• CONEC Hybrid Connectors

• Connectors for agricultural and construction machines

• Circular Connectors

• PCB Connectors

• Customer specific solutions

The company’s quality management ensures high quality by applying the international standards according DIN EN ISO 9001. Depending on the product family, CONEC industrial connectors are tested and approved in accordance with UL, CSA or VDE.

CONEC Elektronische Bauelemente GmbH

Ostenfeldmark 16

59557 Lippstadt

Telefon: +49 (2941) 765-0

Telefax: +49 (2941) 765-65

http://www.conec.com

Marketing Communications Manager

Telefon: +49 (2941) 765-350

Fax: +49 (2941) 765-65

E-Mail: Katja.schade@conec.de

![]()