EMG hotCAM as the basis for a closed control loop with SMS X-Pact® Sense

The online measurement values provided by EMG hotCAM also form an ideal basis for a closed control loop, which in every plant situation should lead to automatic correction of deviations from the optimal strip position in real time and prevent critical plant conditions before they even arise.

In view of this, joint developments have led to EMG hotCAM now also becoming a member of the X-Pact® Sense family of SMS group GmbH. X-Pact® Sense provides plant operators with a wide range of solutions based on visual, acoustic, and haptic evaluations.

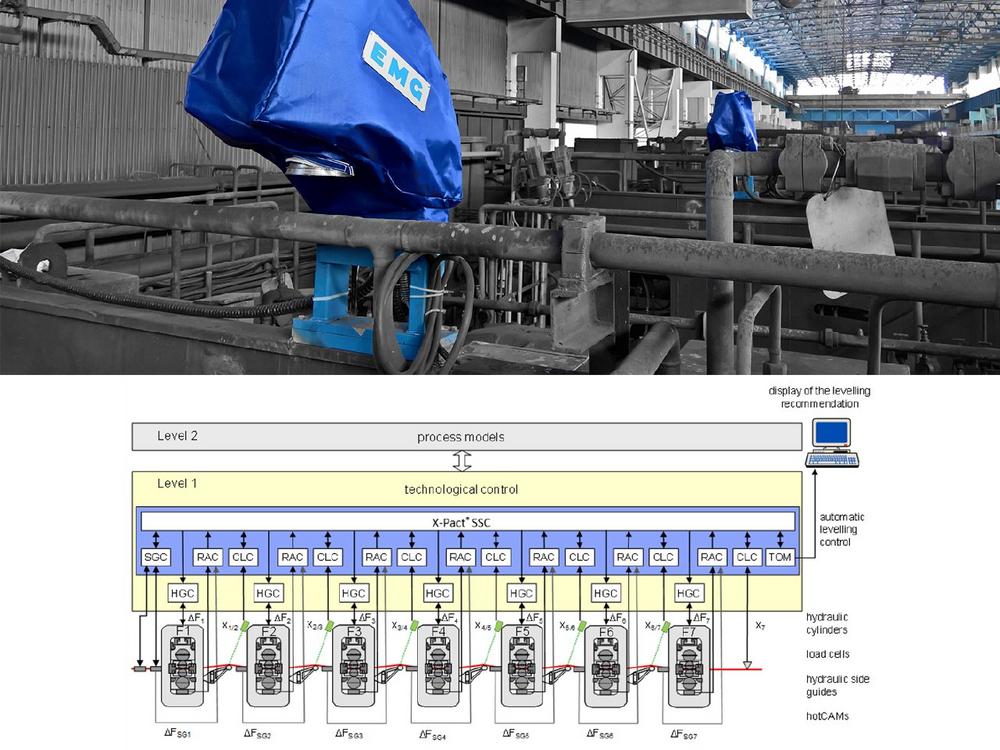

In the specific application case, the described strip guiding control in the hot strip mill consists of two essential modules. On the one hand, this is the EMG hotCAM solution (with one or more cameras) itself and, on the other hand, the automated control – in the form of the ALC (Automatic Levelling Control) of the SMS group – for the real time optimisation of the strip position and improvement of the rolling process. A schematic diagram for the combined automatic strip position control is shown in the lower part of the figure.

The EMG hotCAM system records the position of the strip and the deviation from the centre line in the intermediate stand area between two rolling stands. The measurement information obtained with EMG hotCAM is made available to the Level 1 automation system. Based on this, the X-Pact® control software calculates a correction signal of the hot strip mill’s rolling stands (the "strip centre or position control") so that a closed control loop is created.

The potential benefits of utilising strip position detection by EMG hotCAM and improved strip centre control in the hot strip mill are:

- Increase in rolling stability

- Reduction in the number of unplanned roll changes

- Less rework on the strips

- Documentation of the plant condition and error analysis

- Support of the plant operator through suitable visualisation

- Reduction of cobbles caused by rolling mill instability

- Improvement of the strip quality

This solution is now in continuous use in various finishing mills and is available to all interested parties in the hot rolling sector.

CONCLUSION: In combination with an automation solution in the sense of a closed control loop, EMG hotCAM offers the plant operator considerable potential for minimising damage and increasing yield in the hot rolling process. The integration into the X-Pact® Sense family of the SMS group ensures that the realisation of such a control concept is possible in the proven software and hardware environment of the SMS X-Pact® solutions. The realisation of such a project is independent of the question whether a control landscape with SMS X-Pact® is already in use on site or not. In both cases, EMG and the SMS group offer a tailor-made solution.

Further information:

You want to know more about EMG hotCAM? Perhaps you have completely different ideas about the use of EMG hotCAM technology? Please feel free to contact our international sales organisation or our product management directly at: guido.eichert@emg-automation.com and visit our website.

Download: Brochure EMG hotCAM

elexis AG

Industriestr. 1

57482 Wenden

Telefon: +49 (2762) 612-130

Telefax: +49 (2762) 612-135

http://www.elexis.group

Vice President Global Marketing

Telefon: +492762612126

E-Mail: nicol.otterbach@elexis.de

![]()