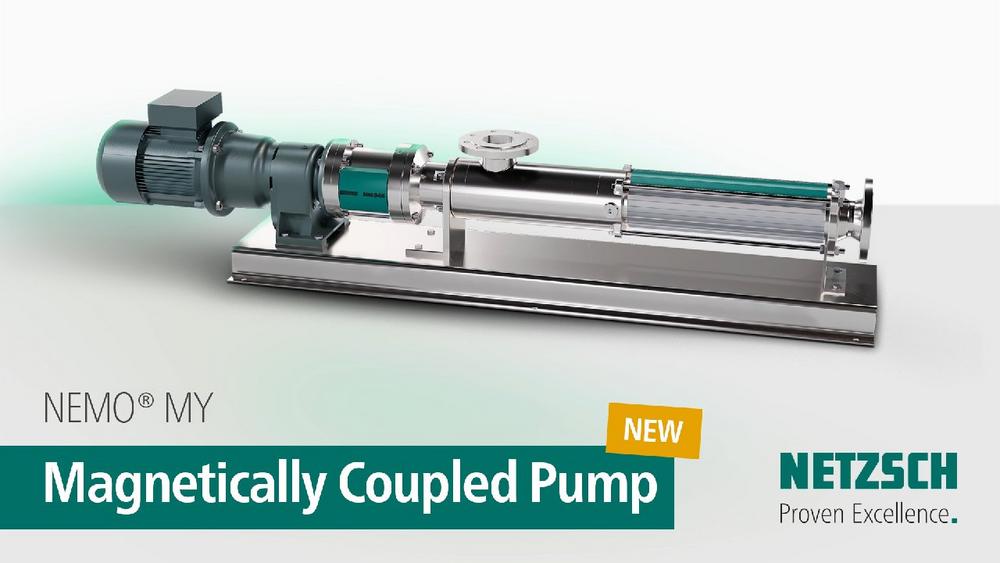

The pump has been specially designed for safer and more sustainable conveying of fluids with high viscosity, such as slurries in battery production. The magnetic coupling of the new NEMO® MY was specially developed by NETZSCH. A special feature of the pump is its complete hermetic seal, which creates a safer working environment by preventing the escape of aggressive, toxic or abrasive liquids and gases. In addition, this contributes to significant cost savings, as sealing systems do not require maintenance and risks that can occur due to leaks are minimised.

The innovative design of the pump enables operation at low speeds of 200 to 300 revolutions per minute, which leads to a significant reduction in mechanical load and thus extends the service life of the drive system.

The NEMO® MY also enables the pumping of extremely viscous media up to 20,000 cps. This application was previously not possible using magnetically coupled pumps. The pump is also suitable for applications that require the ATEX standard and can therefore be used in various applications in the chemical, pharmaceutical and food industries without any problems.

Compared to conventional pumps with mechanical seals or other sealing systems, the further development of the NEMO® offers significant cost advantages. No external services are required to operate the magnetic drive pump. Costs for pressurised gas, sealing liquid or electrical connections for pressure and level switches are completely eliminated.

"With the further development of our NEMO® progressive cavity pump, you can look forward to a real highlight. Cost-intensive mechanical seals or other sealing systems are now a thing of the past,’ says Roger Willis, Global Business Field Manager Chemical, Pulp & Paper.

Visit us at ACHEMA in Hall 8 at Stand C27, we look forward to seeing you!

You are not coming to ACHEMA but would still like to find out more about the latest development, the magnetically coupled pump?

Registere here for our free of cost webinars:

As a global specialist for handling complex media, customer satisfaction is the top priority at NETZSCH Pumps & Systems. We have developed, produced and distributed customised and sophisticated pump solutions for over seven decades. With our NEMO® progressing cavity pumps, TORNADO® rotary lobe pumps, NOTOS® multi screw pumps, PERIPRO® peristaltic pumps, grinders, dosing technology and accessories, we offer innovative solutions on a global scale, from the smallest dosing pump for the industry to large pumps for the oil and gas sector or mining. Even the most demanding media pose no problems for our product portfolio. With over 2,500 employees, NETZSCH Pumps & Systems is the largest business unit of the NETZSCH Group, along with NETZSCH Analyzing & Testing and NETZSCH Grinding & Dispersing. Our performance standards are high. We promise our customers Proven Excellence – exceptional performance in everything we do, proven time and again since 1873.

NETZSCH Pumpen & Systeme GmbH

Geretsrieder Straße 1

84478 Waldkraiburg

Telefon: +49 (8638) 63-0

Telefax: +49 (8638) 67981

http://pumps-systems.netzsch.com

PR & Communications

Telefon: +49 8638 631594

E-Mail: stephanie.schwabe@netzsch.com

![]()