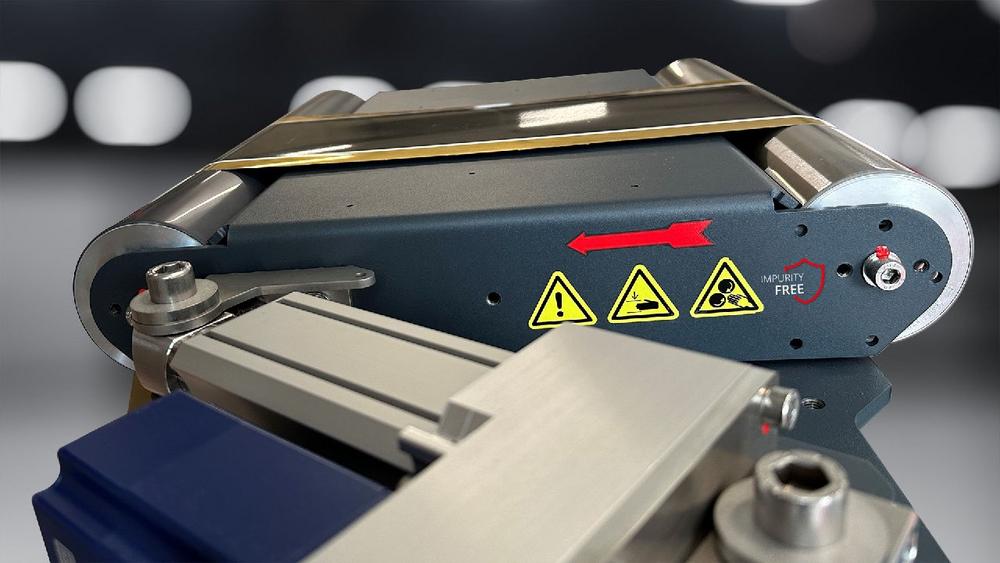

From coating, drying, calendering, stacking and winding to inserting the cell into the battery casing – battery cell production is a demanding and complex process that involves many individual steps, each with different quality criteria and potential sources of error. Among other things, it is important to avoid substances during production that could get onto the track as abrasion or dust and contaminate it. These include copper, zinc and nickel in particular. Through the introduction of “Impurity Free” label, BST GmbH showcases its flexibility and sustainability in adjusting material usage in its quality assurance systems, ensuring they meet the highest quality standards and customers can work with them safely.

Copper, zinc and nickel limited to a minimum

In order to minimize safety risks and functional defects and thus ensure sustainable and efficient battery cell production, BST has limited the use of copper, zinc and nickel to a minimum in many of its solutions for parts that could come into contact with the track. This effectively prevents contamination from the smallest material particles. Material rejects or even product recalls due to safety risks or functional defects are therefore a thing of the past. For better orientation for customers, these products, which have been specially developed for use in the environment of battery materials, feature the new BST "Impurity Free" seal. Of course, this does not affect the function of the systems in any way. Currently, the product range labeled "Impurity Free" primarily includes solutions for web guiding. In future, BST systems from other product areas will also be adapted accordingly.

Suitable for drying rooms down to minus 70 °C

An additional further development of the "Impurity Free" solutions concerns dry room suitability: In lithium-ion cell production, it is common to use a dry room environment with a pressure dew point between -50 °C and sometimes -70 °C. This special environment serves to minimize the risk of harmful acids forming due to ambient humidity and thus extend the service life of the batteries. The BST "Impurity Free" solutions are also up to this challenge. They can be used reliably in extremely dry environments with pressure dew points from -30 °C to -70 °C. With these advanced quality assurance systems, BST offers customers exactly what counts in battery cell production today: Maximum safety, maximum performance and 100 percent quality under highly efficient, sustainable manufacturing conditions.

Further information is available at Copper zinc and nickel in battery production (elexis.group)

BST GmbH, an elexis Group company, is one of the leading suppliers of quality assurance systems for web processing industries. The Bielefeld-based company offers solutions for web guiding, surface inspection, web monitoring, 100% inspection, color measurement, color management, register control and automation. The company has decades of practical expertise in these areas, with installations at more than 15,000 customers worldwide in the printing and packaging, paper and film, rubber and tire, battery and fuel cell, and printed and organic electronics industries. BST stands for high-quality quality monitoring, smooth production processes and first-class service worldwide.

www.bst.elexis.group

elexis AG

Industriestr. 1

57482 Wenden

Telefon: +49 (2762) 612-130

Telefax: +49 (2762) 612-135

http://www.elexis.group

Head of Corporate Communications

Telefon: +492762612286

E-Mail: konrad.huenerfeld@elexis.de

![]()