In the building shell, thermal and solar control layers have been very efficient measures for over 40 years, reducing heating and cooling costs by up to 80 percent. VON ARDENNE has been one of the world’s leading coating technology companies for three decades. The company also offers its mature technology in the automotive glazing market, where coatings reduce the energy consumption of airconditioning systems and help electric vehicles achieve a greater range.

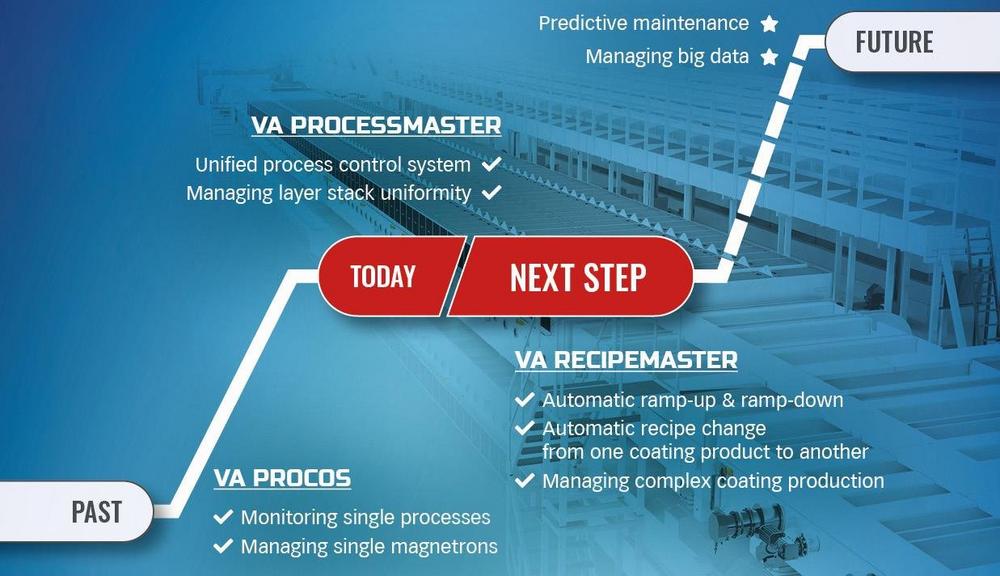

While measures to make more efficient use of the resources employed have largely been exhausted on the hardware side, further potential lies in software-supported optimizations. VON ARDENNE has been consistently pursuing this approach for several years under the name VA INDIGO.

VON ARDENNE’s software solution VA INDIGO raises further potential for savings

Under the umbrella brand VA INDIGO, the Dresden-based high-tech company offers for the first time in large-area coating a solution for monitoring and controlling not only individual processes, but complete optical layer stacks: the VA PROCESSMASTER.

With VA PROCESSMASTER, machine operators are provided with tools that ensure that the optical coating result is produced in a stable manner. The hardware for the operation of VA PROCESSMASTER is already available in many coating systems. Therefore, the software can be put into operation with little effort.

Algorithms help to determine and monitor the optimum operating point of the sputtering process. If the desired deposition rate can be achieved with the minimum energy required, this reduces energy consumption, the peak load of the production equipment and thus also production costs. This is ensured by VA TIPCOS, which is already successfully in use.

VA RECIPEMASTER comes up with a powerful and comprehensive recipe architecture and makes it possible to automate the ramp-up of and the switching between different procedures in production. The software thus translates best-practice experience of machine operators into fixed algorithms and ensures reliable production with lower manpower requirements. In this way, more and more processes can be automated, the risk of human error as well as the number of possible causes in the event of an error can be reduced: The coating system can be put back into operation more quickly, and the productivity of the resources used increases.

Benefits in a nutshell

VON ARDENNE software solutions ensure significantly higher yields, even for very complex coatings of glass panes such as architectural or automotive glazing. This saves consumables during production and thus energy during recycling. And it enables longer equipment availability.

This is also ensured by further digital tools such as AR glasses, which VON ARDENNE uses to support its customers with specialist expertise in real time over long distances. In many cases, this eliminates the need for service technicians to travel long distances and reduces greenhouse gas emissions.

Invitation to the presentation "Digital solutions for resource efficiency in vacuum coating"

We would like to invite you to learn more about this topic. Dr. Harald Hagenström (Vice President Glass at VON ARDENNE) will be happy to give you an overview of the advantages that VON ARDENNE’s "Digital Solutions for Resource Efficiency in Vacuum Coating" offer in his presentation on 20 September 2022 at 11:20 am in hall 11 at booth B24.

VON ARDENNE AT THE GLASSTEC 2022 IN DÜSSELDORF

DATE: 20 – 23 September 2022

BOOTH: hall 12 / E49

VON ARDENNE develops and manufactures systems for the industrial vacuum coating of materials, such as glass, wafers, metal strips or polymer films. Depending on the application, these coatings are one nanometer to a few micrometers thin and give the materials new functional properties. Our customers use these materials to produce high quality products, such as solar cells and solar modules, architectural glass and vehicle glazing, fuel cells, lithium ion batteries or microelectronic components for sensor systems and optics. Systems and components provided by VON ARDENNE make an important contribution to protecting our environment. They are crucial when producing products that help to consume less energy or that generate energy from renewable resources.

With more than 60 years of experience in electron beam technology and over 45 years of experience in magnetron sputtering, VON ARDENNE is a pioneer and worldwide leading supplier of systems and technologies in PVD thin-film and vacuum process technology. We offer our customers technologically mature vacuum coating systems, comprehensive expertise and global service. The key components are developed and manufactured in-house at VON ARDENNE.

VON ARDENNE GmbH

Am Hahnweg 8

01328 Dresden

Telefon: +49 (351) 2637-300

Telefax: +49 (351) 2637-308

http://www.vonardenne.de

Corporate Communications

Telefon: +49 (351) 2637-9000

E-Mail: bauer.ingo@vonardenne.biz

![]()