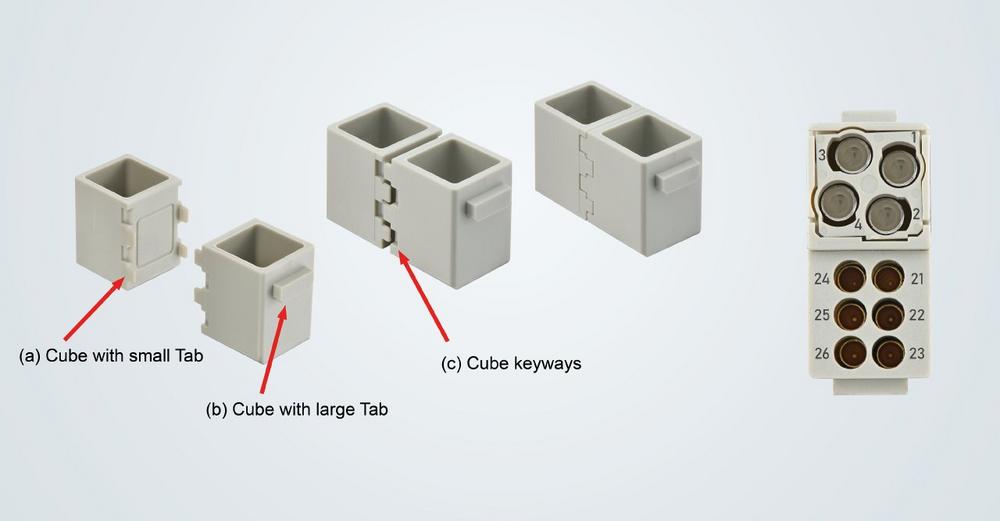

In the same way as a domino is divided into two separate fields, a Domino module consists of two elements, called “cubes”, which are half the size of traditional Han-Modular® modules. The cubes can be combined to form “individual” Domino modules in the connector in accordance with requirements. This increases flexibility when equipping rail vehicles with interfaces. More connection solutions can be effectively accommodated within the same installation space using the Domino modules in typical housings for the cable-based transfer of power, data and signals between carriages – e.g. Han® 24 and 34 HPR EasyCon as well as Han® HPR Compact.

The cubes can be combined as needed in the Domino module. Pin and socket contacts can also be sited together on one side of the interface. Various arrangements of data, signal and power modules are possible. Using just a few basic elements, a whole range of connection options can be created which can be scaled to meet requirements.

The Han® Domino modules meet the need for flexible solutions and savings in installation space and weight in rail transport equipment. Fitters and service technicians benefit from considerably shorter installation times as modular connectors are generally easier to install than several individual interfaces for different types of transmission. The Domino modules are compatible across the board with the components of the Han-Modular® series, the previous market standard for modular connectors.

The following cubes are available:

- Han® Domino DD Cube for up to 6 crimp contacts with 10 A / 250 V

- Han® Domino EE Cube for up to 4 x Han E crimp contacts with 16 A / 400 V

- Han® Domino HD Cube for up to 16 x D-Sub contacts (4A / 32 V)

- Han® Domino M12 Cube for one M12 contact (D- or X-coded up to 10 Gbit/s)

- Han® Domino Pneumatic Cube with one pneumatic metal contact (3; 4; 6 mm)

- Han® Domino dummy cube as a placeholder for future extensions

Benefits:

– up to 50% space saving for interfaces

– can be combined with the proven Han-Modular® series: existing supporting frames, housings and connector modules can continue to be used

– systematic continuation of modularisation process and enhanced future-proofing of solutions

– reduced installation times for interfaces (process optimisation)

– finer-grained scalability of interfaces, to fit the relevant equipment

The HARTING Technology Group is one of the world’s leading providers of industrial connection technology for the three lifelines of Data, Signal and Power and has 14 production plants and 44 sales companies. Moreover, the company also produces retail checkout systems, electromagnetic actuators for automotive and industrial series use, charging equipment for electric vehicles, as well as hardware and software for customers and applications in automation technology, mechanical and plant engineering, robotics and transportation engineering. In the 2020/21 business year, some 6,200 employees generated sales of EUR 869 million.

HARTING Stiftung & Co. KG

Marienwerderstr. 3

32339 Espelkamp

Telefon: +49 (5772) 47-0

Telefax: +49 (5772) 47-400

http://www.HARTING.com

Zentralbereichsleiter Publizistik und Kommunikation

Telefon: +49 (5772) 47-244

Fax: +49 (5772) 47-400

E-Mail: Detlef.Sieverdingbeck@HARTING.com

Manager Media and Publications

Telefon: +49 (5772) 47-9982

Fax: +49 (5772) 47-400

E-Mail: lars.kuehme@HARTING.com

![]()