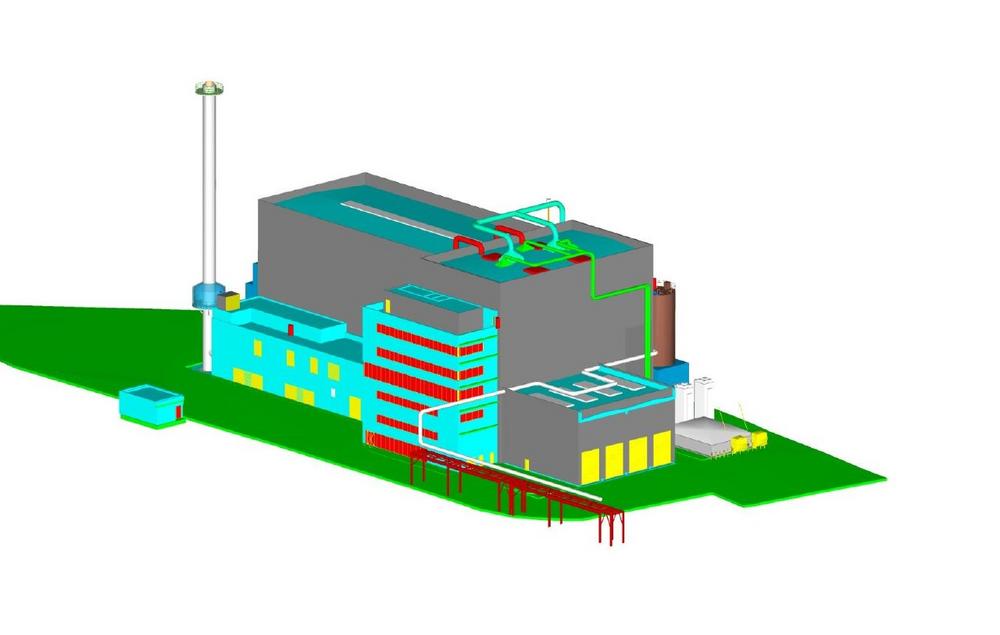

One process line will be supplied, including a stationary fluidised bed furnace, steam generator, multi-stage flue gas cleaning and water-steam cycle. The Flemish municipal wastewater treatment company Aquafin has awarded the DBFMO contract for the new plant to FOSTER, a consortium consisting of BESIX Group and Indaver NV.

Recovery of phosphorus

After completion, the new sewage sludge treatment plant, which will be one of the largest in Europe, will thermally treat 65,000 tonnes of dry substance per year. Mono-incineration will enable valuable phosphorus, which is listed by the EU as a critical raw material, to be extracted from the separated ash in a further process step.

Compliance with all emission directives

The modern flue gas cleaning system consists of selective non-catalytic reduction and a combination of wastewater-free dry and wet processes. Two heat exchangers are installed for optimum utilisation of the residual heat contained in the flue gas. The recovered heat is used for feedwater preheating.

The multi-stage gas cleaning process reliably removes all relevant pollutants such as nitrogen oxides, acid gases, hydrocarbons, and heavy metals from the flue gas. Strict emission requirements in accordance with the European BREF (Best Available Techniques Reference) directives are fully complied with.

High plant efficiency

"Our customer will be in a position to realise a reliable and future-proof disposal of municipal sewage sludge in the Ghent region with the help of our technologies," explains Sebastian Seibel, Bid Manager at Doosan Lentjes. "In this context, the fluidised bed process used offers extensive advantages: excellent heat and mass transfer conditions in the fluidised bed furnace maximise combustion efficiency. This not only ensures self-sufficient plant operation, but also makes it possible to use the steam produced with the waste heat from the flue gas for external applications. Steam that is not needed for plant operation is fed to the high-pressure turbine of a neighbouring industrial plant that uses the energy as part of its steel production."

Re-entry into the market for sewage sludge treatment

Dr. Thorsten Becker, Division Manager Sales & Proposals at Doosan Lentjes, adds: "With this latest order, we have succeeded in re-entering the business field of thermal sewage sludge treatment. The success shows that our technologies, which cover the entire process chain of sewage sludge incineration, are in demand on the market and meet the requirements. As an experienced plant manufacturer, we are pleased to handle the project while considering the objectives of all the stakeholders involved."

In 2018, Doosan Lentjes had resumed its earlier involvement in the market for the thermal treatment of municipal sewage sludge. The background to this decision was corresponding new legal regulations, which led to the expectation of a positive market development in Germany, but also in Europe.

In re-entering the market for the thermal treatment of municipal sewage sludge, Doosan Lentjes draws on extensive experience. For many years, the company designed and built plants for customers in Germany and Europe as a general contractor. A declining market volume prompted Doosan Lentjes to reduce its involvement in this business field a few years ago. Since then, however, both fluidised bed and flue gas cleaning technology have continued to be used in various areas.

Doosan Lentjes is headquartered in Ratingen, Germany, and is part of the Korean Doosan Group.

Doosan Lentjes provides proprietary environmental technologies for thermal waste treatment and energy generation. Our areas of expertise include the incineration of renewable fuels such as waste, sewage sludge and biomass, heat recovery systems and flue gas cleaning equipment. We deliver flexible solutions for long-term waste disposal safety and climate-friendly steam and power generation.

As a member of the global Doosan Group, Doosan Lentjes is part of a strong international network of companies providing complementary technologies, skills and value to customers the world over.

Doosan Lentjes GmbH

Daniel-Goldbach-Straße 19

40880 Ratingen

Telefon: +49 (2102) 166-0

Telefax: +49 (2102) 166-2500

http://www.doosanlentjes.com/en/

Senior Marketing Manager

Telefon: +49 (2102) 1661476

Fax: +49 (2102) 1662476

E-Mail: diana.baganz@doosan.com

![]()