Changes in the Furniture Industry – New Fulfillment Approaches in Demand

The corona pandemic has changed furniture e-commerce in a very short time. Customers have realized that they can order even fairly large pieces of furniture conveniently online. A survey by Technavio Research forecasts worldwide growth of USD 84.26 billion in furniture e-commerce between 2020 and 2024. Traditional suppliers must respond to this development and implement suitable multi-channel picking strategies that can also meet the demand for on-time delivery associated with e-commerce business for same-day/next-day delivery. Otherwise, they risk losing market share. At the same time, the furniture industry is facing extremely fierce price competition and is looking for solutions to permanently reduce order processing costs. Another challenge is the range of products. It is very heterogeneous and sometimes involves heavy, bulky goods, which are usually difficult to handle manually. This has increased the demand for an ergonomic solutions to prevent musculoskeletal disorders of warehouse professionals and to make work in the warehouse more attractive in general.

Flat Pack Picking – Picking Heavy and Bulky Items Efficiently and Automatically

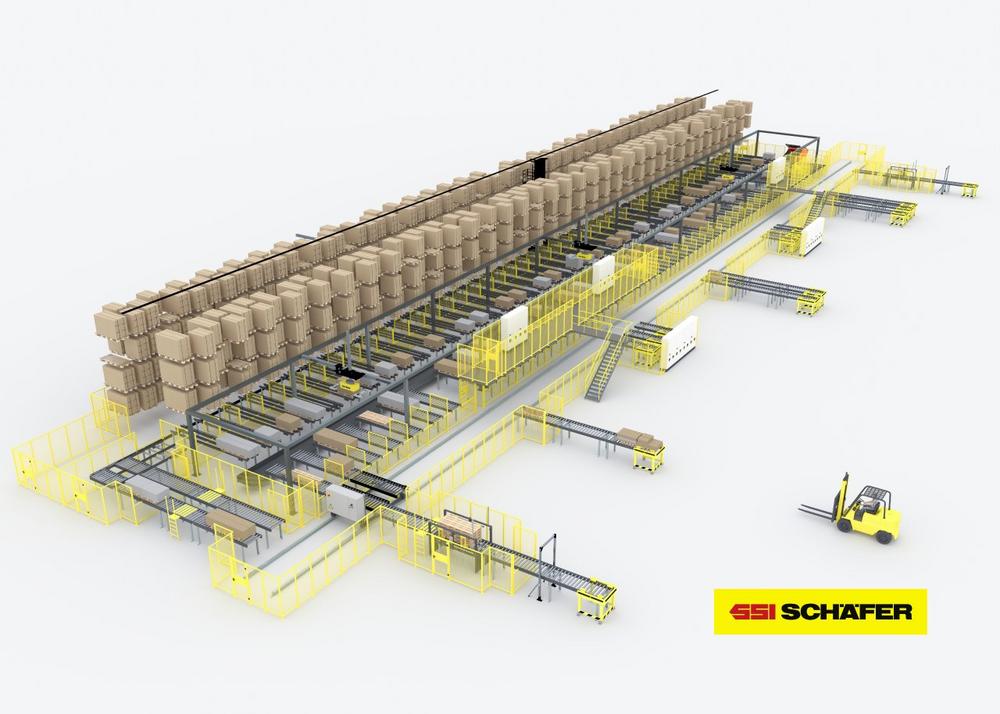

To help the furniture industry meet these challenges, SSI Schaefer has developed the flat pack picking solution – a turnkey system for safe, fully automated handling of a wide range of SKUs (Stock Keeping Units) in the furniture industry. The solutions is the result of an initiative of SSI Schaefer specialists in the “Retail & Wholesale” sector, which was brought to market in cooperation with a multinational furniture corporation.

Gantry robots take over the picking of heavy and bulky items, allowing staff to focus on handling lighter and smaller items. SSI Schaefer supplies the flat pack picking module, including both the hardware and software, from a single source. It is designed for high performance, can be scaled flexibly and allows compact installation in both new and existing warehouses with limited floor space. Another characteristic feature is efficient palletizing: Using intelligent algorithms, the system automatically generates packing patterns based on the various SKU specifics to optimize the stability of the load on the order pallets and reduce the volume.

Handling a Heterogeneous Product Spectrum Flexibly and Efficiently

The solution combines a high-bay warehouse, which serves as an automatic pallet buffer for picking, with gantry robots to create an efficient overall solution. After they pass through a contour/weight check, the conveying system moves the pallets to the in-feed drives of the high-bay warehouse. There, energy-efficient SSI Exyz storage-retrieval machines (SRM) store them temporarily. Pallets are retrieved for picking on an as-needed basis, although how the source pallets are made available depends on the classification of the items stored on them. For pallets with fast movers, the storage-retrieval machine transfers them to a shuttle car, which then places them on static picking stations. Slow movers, by contrast, are transported directly from the storage-retrieval machine to conveyor branches (the connecting conveying system), which make them available dynamically for picking. When no longer required, opened source pallets of slow movers are returned to storage in the same way.

Along the buffer aisle, four RO-BER FP150 series gantry robots pick orders, accessing both statically provided A-items and dynamically provided B- and C-items within their action area. The gantry robots are equipped with multifunctional grippers that automatically adapt to the dimensions of the items and the type of packaging by means of servo-motor-adjustable suction cups. RO-BER Industrieroboter GmbH, a subsidiary of SSI Schaefer, developed the gantry robots and grippers. Vision technology, in combination with the WAMAS® logistics software, supports this process, allowing each picking robot to quickly identify the proper position of the requested item. Goods up to 2.5 m in length and weighing more than 60 kg are safely picked up from the source pallet and transferred to the ready-to-use order pallet. The removal of intermediate layers is also fully automated. The stored packing pattern generator, SSI Pack Pattern Generator, ensures a safe, optimized arrangement of the items on the order pallets, which are prepared for further processing via a buffer as part of the outbound process.

Consistent Performance and Attractive Working Conditions

“With flat pack picking, we now offer the first integrated solution to handle the specific requirements of the furniture business within one system,” says Tim Langenbach, Director of Business Development – Retail & Wholesale/Food Retail at SSI Schaefer. “We were able to use a simulation to demonstrate that, with four gantry robots, it is possible to achieve up to 290 picks per hour given an appropriate order structure.” Since replenishment and picking are fully automated, this approach achieves a consistently high level of performance. Flat pack picking frees staff from monotonous work. This increases the motivation.

Cost Optimization and a Quick Return on Investment (ROI)

The highly innovative flat pack picking solution makes it possible to handle both orders for delivery to brick-and-mortar furniture retailers and online orders placed by the end customer in parallel – quickly, reliably and efficiently. Compared to tunnel picking, which requires walkways and separate replenishment areas, the automated solution also takes up around 50% less space. “Operators benefit from reduced logistics costs per order and also save on fixed costs, so the investment pays for itself quickly,” says Tim Langenbach in summary. SSI Schaefer supplies this system solution, tailored to the requirements of the furniture industry, all from a single source and produces all the components – from the hardware to the software – itself, they are all carefully coordinated. This ensures the highest level of quality, sustainability and investment security. The flat pack picking solution has a modular design, can be scaled flexibly and can be adapted at any time to the further business volumes growth in the e-commerce sector that is forecast for the industry in the post-COVID era as well. In addition, the concept can be carried over to other industries that deal with large-volume and bulky goods, such as radiators, windows, wood/metal blanks or fence elements.

The SSI Schaefer Group is the world’s leading provider of modular warehousing and logistics solutions. With headquarters located in Neunkirchen (Germany), SSI Schaefer employs approximately 10,000 associates globally, along with seven domestic and international production sites, and approximately 70 worldwide operating subsidiaries. Across six continents, SSI Schaefer develops and implements innovative industry-specific answers to its customers‘ unique challenges. As a result, it plays a key role in shaping the future of materials handling.

SSI Schaefer designs, develops and manufactures systems for warehouses and industrial plants. Its portfolio includes manual and automated solutions for warehousing, conveying, picking and sorting, plus technologies for waste management and recycling. In addition, SSI Schaefer is now a leading provider of modular, regularly updated software for in-house material flows. Its software team, with a headcount in excess of 1,100, develops high-performance applications, and provides customers with in-depth advice on the intelligent combination of software with intralogistics equipment. The SSI Schaefer IT offering, including its own WAMAS® and SAP products, delivers seamless support for all warehouse and material flow management processes. Solutions from SSI Schaefer improve the productivity and efficiency of customer organizations – not least through the highly precise monitoring, visualization, and analysis of operational metrics for proactive intralogistics management.

SSI Schaefer offers highly sophisticated, turnkey systems. As an international player, it can deliver one-stop solutions to all four corners of the earth. Its comprehensive portfolio encompasses design, planning, consulting, and customer-specific aftersales services and maintenance.

SSI SCHÄFER

Fritz-Schäfer-Strasse 20

57290 Neunkirchen / Siegerland

Telefon: +49 (2735) 70-1

Telefax: +49 (2735) 70-396

http://www.ssi-schaefer.de

Junior Project Manager CR & PR | Global Marketing

Telefon: +49 (2735) 70-9683

Fax: +49 (2735) 70-382

E-Mail: Annika.Nolte@ssi-schaefer.com

Marketing & Kommunikation

Telefon: +49 (2735) 70-252

Fax: +49 (2735) 70-382

E-Mail: melanie.kaempf@ssi-schaefer.de

![]()