Update Digital Twin without errors

"Maintenance or asset management do not think in terms of bills of materials, but in terms of devices and functional locations," explains Dr Pouria Bigvand, Head of Product Management at Aucotec, "which is why we have extended EB’s ERP/PLM interface for asset management issues." This means that EB can now also support and accelerate the management of maintenance intervals with all the necessary engineering data on the affected devices. And the relevant changes made in the physical plant flow more quickly to EB. In this way, the interface updates the digital twin and thus the plant documentation without errors. This updating, in turn, is the essential basis for the efficiency of the next maintenance action. "Above all, this will make the work of plant operators easier," says Bigvand.

Neutral and flexible

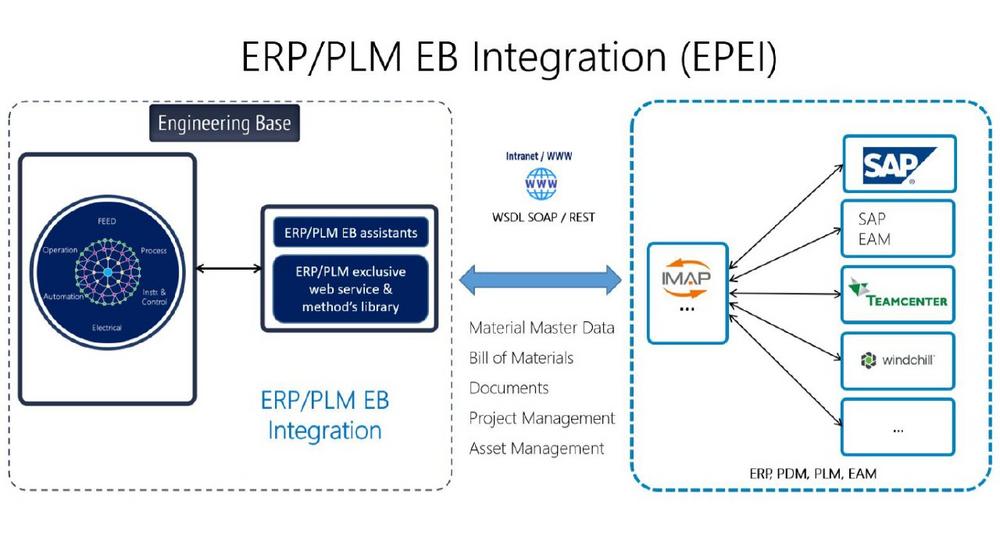

The basis on the EB side is a standard interface that outputs EB’s engineering data in a neutral language. This ERP/PLM-EB integration (EPEI), which now also enables exchange with the EAM module of SAP’s ERP Business Suite, is just the first real-life example of the new connectivity to maintenance and asset management systems. "This connection immediately proves its special openness and flexibility, because SAP EAM is very complex," says the product manager.

For the ERP side, there is a standard middleware developed in cooperation with Aucotec’s partner it-motive, which translates EB’s neutral data virtually into any ERP dialect, whether from SAP or other providers, and which has now also been extended. EB’s neutral EPEI language can also be "taught" to any company’s own middleware. The data exchange between EB and asset management can run via web services, i.e. client and time zone independent. This allows for automated intervals that do not interfere with everyday work.

Control is better

In addition, the integration solution can be supplemented with an approval app, via which an independent authority must first approve the maintenance and engineering actions before the data is passed on. "This workflow is particularly in demand from our customers from the energy sector," reports Pouria Bigvand. Aucotec’s EPEI solution is scalable depending on the purpose: pure ERP/PLM integration, connection to SAP EAM only or both together.

Aucotec AG has more than 35 years’ experience in the development of engineering software designed for use throughout the service life of machinery, plant equipment and mobile systems. Solutions range from flow diagrams and process-control/electrical technology for large-scale plant systems to modular on-board power supply units designed for the automotive industry. Software supplied by Aucotec is currently in operation throughout the world. In addition to the headquarters in Hanover, the Aucotec Group includes six other locations in Germany as well as subsidiaries in China, South Korea, France, Italy, Austria, Poland, Sweden, Norway and the USA. What is more, a global partner network ensures local support all over the world.

AUCOTEC AG – EN

Hannoversche Straße 105

30916 Isernhagen

Telefon: +49 (511) 6103-0

Telefax: +49 (511) 614074

http://www.aucotec.com

Presse & Öffentlichkeitsarbeit

Telefon: +49 (511) 6103-186

Fax: +49 (511) 614074

E-Mail: jki@aucotec.com

![]()