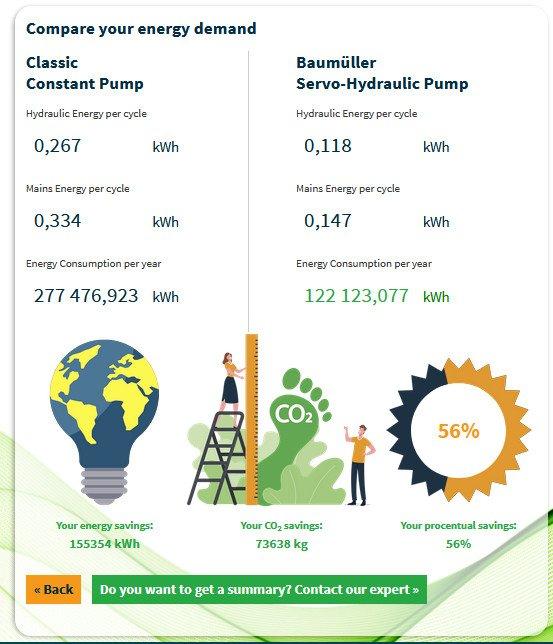

Depending on the application, changing from hydraulic to servo-hydraulic technology for a hydraulic machine can save more than 50 percent energy (kWh) per cycle. Baumüller, the drive and automation specialist now provides an online energy calculation with which the savings for the respective machine can be calculated, in only three steps. An overview compares the energy consumption of a classic constant pump with that of a servo-hydraulic pump.

The online calculator is available at https://www.baumueller.com/en/energy-calculator. Enter the duration, pressure and flow rate of the individual segments and the hydraulic energy and electricity consumption per cycle and the total energy consumption per year are calculated. The consumption values of a classic constant pump and the Baumüller servo-hydraulic pump are shown clearly next to each other. The CO₂ footprint is displayed graphically at the end of the comparison, based on energy saving, CO₂ saving and percentage saving. The summary of the results and a consultation can be requested in a further step, if you wish. The data entered can then be used directly for the specific component design, without further input.

The Best of Both Worlds: Combine hydraulics and servo technology and save energy costs

Classic hydraulic applications have many advantages: The hydraulics ensure high force and power density and that a large number of actuators can be activated with only one drive. The drive elements are robust and comparatively low-cost. In many cases, including hydraulic and hybrid plastics machines and presses, servo-hydraulic drive solutions can further improve the machine’s efficiency and performance.

Servo-hydraulic machines combine the advantages of hydraulic power transfer with the features of servo-drive technology: High power densities, compact drive units, and costeffective and robust drive elements team up with dynamic and precise speed control. The energy consumption of the drive system thus reduces significantly and also allows for shorter cycle times, greater accuracy as well as lower noise development.

With the new Baumüller energy calculator, the energy saving can now be calculated quickly and easily online.

A short video about how to use our energy calculator is published at https://youtu.be/K6-EofxGWTs .

www.baumueller.com/de/aktuelles/presse

https://www.youtube.com/user/BaumuellerGroup

https://www.xing.com/companies/baumüllergruppe

https://www.linkedin.com/company/baumueller-nuernberg-gmbh

Based in Nuremberg, Baumüller is a leading manufacturer of electric automation and drive systems. At production sites in Germany, the Czech Republic, Slovenia and China as well as in over 40 branches worldwide, around 2,000 employees develop and produce intelligent system solutions for machine manufacturing and e-mobility.

In addition, the range of services offered by the Baumüller Group includes engineering, assembly and industrial relocation as well as services, thus covering all aspects of life cycle management.

Baumüller Gruppe

Ostendstraße 80-90

90482 Nürnberg

Telefon: +49 (911) 5432-0

Telefax: +49 (911) 5432-130

http://www.baumueller.com

Marketing Manager

Telefon: +49 (911) 5432-274

E-Mail: leonhard.kemnitzer@baumueller.com

Marketing Communications Manager

Telefon: +49 (911) 5432-319

E-Mail: stefanie.lauterbach@baumueller.com

![]()