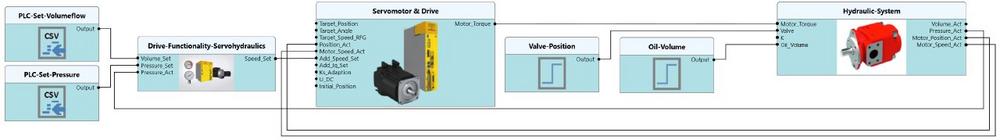

By mapping pump properties such as the volumetric and hydraulic-mechanical efficiency, and taking into consideration system properties such as variable oil volume, pipe losses and leakage behavior, complete servo hydraulic applications can be designed in the simulation and commissioned virtually. These events can be transferred to the real application later, as a result of which, the time and cost of developing and commissioning servo hydraulic machines and systems reduces significantly.

Simulating critical states and testing them in advance

With ProSimulation, not only can the ideal controller settings for the subsequent machine be determined. In a further step, critical states can also be simulated and the effects on the process and the behavior of the drive system can be tested.

One example is the controller-integrated “thermal pump protection” function. This smart function is available as an optional feature for Baumüller servo converters and prevents a thermal overload in the hydraulic system, which can occur in the machine cycle, particularly in case of long hold times of high pressures and low flow. This increases wear and can lead to premature pump failure. A temperature model is directly used in the controller to calculate the pump’s thermal capacity utilization. If a critical threshold value is reached, hydraulic bypasses are connected to relieve the pump, which in turn ensures higher flow and improved heat transfer. This shifts the pump’s operating point out of the temporarily allowable operating range and into the continuously allowable operating range and prevents damage due to hot running.

The hydraulic system can be set up and tested completely virtually in ProSimulation first. In the second step, the machine cycle is simulated and tested for thermal overload of the pump. If critical operating points occur, the pump protection function described above can also be activated in the simulation. In this way, critical operating points can be identified and avoided during the development process.

Reduce development costs and faster on the market

The new functions in ProSimulation expand the area of use of drive simulation for machine manufacturers substantially, and they increase efficiency in the development process, and reduce the Time2Market significantly. In view of rising costs and competitive pressure, in this way, mechanical engineers can further optimize their internal processes. At the same time, the optimal controller settings can be tested directly on the model and used for the subsequent application. The parameters for the drive then only have to be loaded by the application engineer during the real commissioning. Plug & Play for the optimal cycle times.

Drive simulation also promotes sustainability: Through exact design of the motors, overdimensioning of the servo drive is avoided. The motors run within the optimized load range. Depending on the machine running time, energy costs can be saved in this way. Additionally, the machine’s footprint is also optimized.

ProSimulation live

From November 23 – 25, 2021, the Baumüller experts will show in expert calls, how the “thermal pump protection” function can be simulated in ProSimulation.

Based in Nuremberg, Baumüller is a leading manufacturer of electric automation and drive systems. At production sites in Germany, the Czech Republic, Slovenia and China as well as in over 40 branches worldwide, around 2,000 employees develop and produce intelligent system solutions for machine manufacturing and e-mobility.

In addition, the range of services offered by the Baumüller Group includes engineering, assembly and industrial relocation as well as services, thus covering all aspects of life cycle management.

Baumüller Gruppe

Ostendstraße 80-90

90482 Nürnberg

Telefon: +49 (911) 5432-0

Telefax: +49 (911) 5432-130

http://www.baumueller.com

Marketing Communications Manager

Telefon: +49 (911) 5432-319

E-Mail: stefanie.lauterbach@baumueller.com

Marketing Manager

E-Mail: L.Kemnitzer@baumueller.de

![]()