Generally, the supply chains are spread around the world and the products are supplied to customers that need them for a wide range of industrial applications. The market for industrial chemical packaging is therefore characterised by the use of packaging technology that reliably protects chemical products during storage and transport and encloses them in a particularly secure way. The main purpose of packaging in the chemical industry is to prevent spills, explosions, the ingress of moisture, and corrosion. It therefore needs to ensure better shelf life and greater protection against moisture and leaks.

Clear rules for chemical packaging

In Germany and the rest of Europe, the EU Regulation on the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) controls the handling of chemicals. Within the EU, the classification, marking and packaging of chemical substances and mixtures is also governed by the CLP (Classification, Labelling and Packaging) Regulation, which incorporates the UN GHS (Globally Harmonized System of Classification and Labelling of Chemicals).

The CLP stipulates that the packaging for a hazardous chemical substance must be designed, constructed, and fastened in such a way that the contents cannot escape. Due to these stringent requirements, the packaging material must be particularly strong and solid and ensure that the contents cannot be damaged. Special provisions apply when chemical substances are supplied to the public. For example, the packaging must not attract or arouse the curiosity of children or mislead consumers. It must also not have a similar presentation or design to that used for foodstuffs, animal feed, medicinal or cosmetic products. In addition, the packaging must use child-resistant fastenings or closures and tactile warnings of danger (TWDs).

Dynamic market

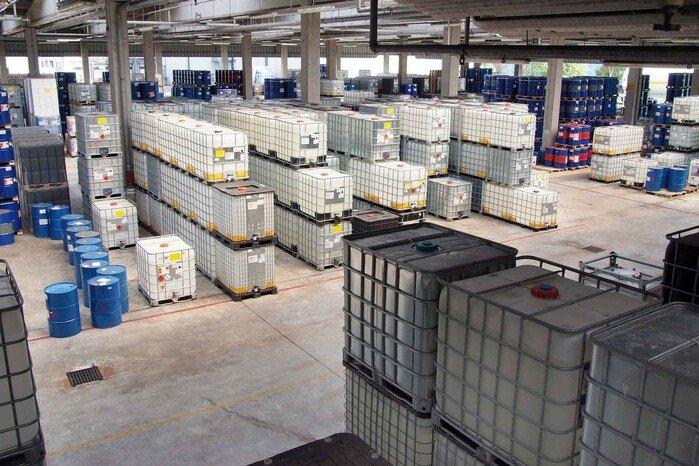

The most important types of packaging used in this industry are bags and sacks, drums, rigid bulk containers and packaging for laboratories. They are subdivided into packaging for hazardous and non-hazardous chemicals. Generally, bulk containers and intermediate bulk containers (IBCs) are used for hazardous substances.

A market research report by Research and Markets concludes that the global market for chemical packaging is set to become more important, with an annual growth rate of 1.7% by 2027. According to the report, packaging sacks account for around a third of the total market volume of USD 10.4 billion, while drums account for 23.8% of the total chemical packaging market.

A survey by market research institute Technavio found that one of the most important trends that is defining the growth of the chemical packaging market is the growing demand for packaging sacks with a high barrier effect. These moisture-blocking bags and sacks are used extensively for packaging in the food and chemical industries because they offer better protection from moisture and oxygen and a longer product shelf life.

According to another survey by Technavio, the growing demand for rigid intermediate bulk containers (IBCs) should significantly boost the growth prospects for the global chemical packaging market. Analysts predict an annual growth rate of 6% for this type of packaging by 2024. FIBCs (flexible intermediate bulk containers), also known as big bags or jumbo bags, are a sub-category of IBCs. They can handle more weight at one time and compared with packaging sacks can be loaded with a vehicle in a shorter period.

As in other packaging segments, suppliers of industrial chemical packaging are endeavouring to improve sustainability by implementing take-back systems and recycling concepts. This was already apparent at FACHPACK in 2019, as more and more suppliers showcased sustainable solutions for chemical packaging in line with the event’s focus on “environmentally-friendly packaging”, which will also be the theme in 2021.

In Germany, the take-back programme is regulated by the Packaging Act. If possible, the containers are then reconditioned, i.e. thoroughly cleaned, and refurbished for re-use. In the case of certain chemicals, however, re-use is not possible. The same applies to the recycling of IBCs due to the diffusion of hazardous substances into the plastic. However, metal IBCs can be readily recycled. FIBCs made from plastics are generally single use only, so in this area there is still plenty of potential for an efficient and sustainable recycling concept. Some companies are therefore working on concepts for a closed loop for big bags. 2021 will hopefully also represent a new beginning for the chemical sector and therefore an opportunity to transition to environmentally friendly packaging solutions.

NürnbergMesse GmbH

Messezentrum

90471 Nürnberg

Telefon: +49 (911) 8606-0

Telefax: +49 (911) 8606-8228

http://www.nuernbergmesse.de

Telefon: +49 (911) 860683-55

Fax: +49 (911) 86061283-55

E-Mail: christina.freund@nuernbergmesse.de

![]()