Six Central German research institutes and companies have joined forces for this project in the ”UTILITAS” (”Ultralight structures for commercial vehicles in municipal service operations”) network. Together, they aim at constructing better collection containers made of light metals and fiber composite plastics, which will replace the heavy steel superstructures of classic waste trucks and are about one third lighter. ”This new generation of electric vehicles would then be able to transport as much waste per load as a classic small waste truck,” emphasizes Annett Klotzbach, who heads the Bonding and Fiber Composite Technology group at Fraunhofer IWS Dresden.

Profitable small series and simple repairs required

UTILITAS aims at sustainable and cost-effective solutions supporting municipalities to meet their climate protection goals with locally available resources. ”This is why the alliance is developing not only the container, but also the related practical production technologies,” explains the engineer. ”The important point here is to ensure that the new containers can also be built profitably in small series and be quickly repaired in local workshops”. The project partners are relying on container constructions made of aluminum frames and fiber glass reinforced thermoplastic panels. They are testing various methods to reliably join these materials, comparable to steel constructions: They press, screw and glue, to name just a few.

With laser, heat and cold: Innovative HPCi® joining process development

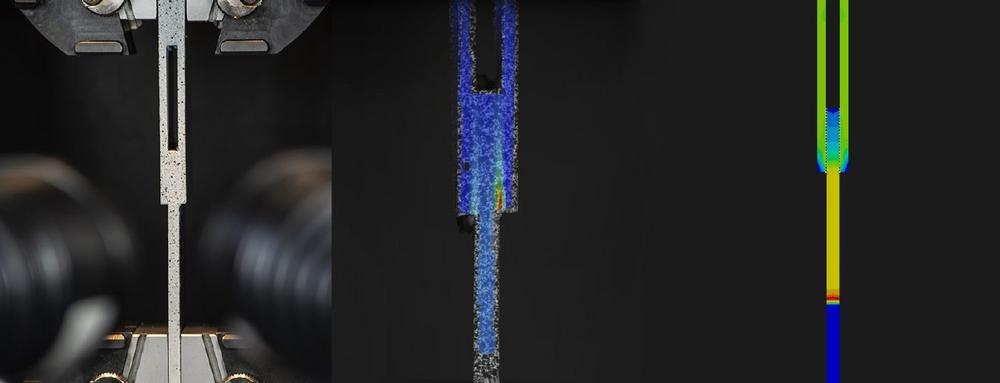

The novel joining technology ”HeatPressCool-integrative” (HPCi®) developed at Fraunhofer IWS is additionally being employed: A laser first roughens the aluminum components, thereby creating grooves in the metal, thinner than a pin and only about 200 micrometers deep. Subsequently, the tool presses the plastic component against the aluminum strut and briefly heats the metal. During this process, the thermoplastic melts on the aluminum surface, flows into the laser-molded grooves and is anchored there during cooling. After a few seconds, aluminum and composite plastic are permanently and firmly bonded.

In the course of the development cooperation, the IWS engineers aim at determining exactly the long-term durability of such a joined lightweight container compared to screw or adhesive solutions. The container will have to withstand high loads in daily use, for example when the vehicle mechanics compress the collected waste. In previous experiments, the HPCi®-joined containers proved to be particularly durable and above all much easier to repair than glued constructions. Measurements have shown that the HPCi® joints can withstand tensile forces equivalent to the pressure of a hydraulic arm of up to 25 megapascals.

Spin-off to produce new joining guns in series

The IWS experts are convinced that the new joining process is not only suitable for waste container constructions, but also for lightweight constructions in aircraft, railways, industrial facilities or ships. Industrial customers also intend to use HPCi® in the production of dishwashers and other household appliances. In order to support the broad practical application of their new joining technology, the Dresden researchers have meanwhile developed compact HPCi® joining guns that are hardly larger than a standard hand drill. They can be modularly mounted on robots, for example, in order to quickly start a small lightweight production run. Since this new tool is so promising, the Fraunhofer scientists also intend to set up a company soon that will series-produce the HPCi® joining guns.

The first electric waste trucks with new lightweight containers will soon shape the urban scene – and the soundscape – of many large cities. ”The container prototypes should be ready by beginning of 2021,” announces Annett Klotzbach. ”We expect the first waste collection vehicles to be on the road within two years.” The developers envisage municipal companies as the main customers. Six partners are involved in the ”UTILITAS” project: Fraunhofer IWS Dresden, the Chair for Structural Lightweight Design and Plastics Processing at Chemnitz University of Technology, Marko Pfaff & Co. Spezialfahrzeugbau GmbH, Car systems Scheil GmbH & Co. KG, the PROFIL Verbindungstechnik GmbH & Co. KG and the EBF Dresden GmbH.

The Fraunhofer-Institut für Werkstoff- und Strahltechnik IWS Dresden stands for innovations in laser and surface technology. As an institute of the Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e. V., IWS offers one stop solutions ranging from the development of new processes to implementation into production up to application-oriented support. The fields of systems technology and process simulation complement the core competencies. The technology fields of Fraunhofer IWS include PVD and nanotechnology, chemical surface technology, thermal surface technology, generation and printing, joining, laser ablation and separation as well as microtechnology. The competence field of material characterization and testing supports the research activities.

At Westsächsische Hochschule Zwickau, IWS runs the Fraunhofer Application Center for Optical Metrology and Surface Technologies AZOM. The Fraunhofer project group at the Dortmunder OberflächenCentrum DOC® is also integrated into the Dresden Institute. The main cooperation partners in the USA include the Center for Coatings and Diamond Technologies (CCD) at Michigan State University in East Lansing and the Center for Laser Applications (CLA) in Plymouth, Michigan. Fraunhofer IWS employs around 450 people at its headquarters in Dresden.

Fraunhofer-Institut für Werkstoff- und Strahltechnik IWS

Winterbergstraße 28

01277 Dresden

Telefon: +49 (351) 83391-0

Telefax: +49 (351) 83391-3300

http://www.iws.fraunhofer.de

Leiter Unternehmenskommunikation

Telefon: +49 (351) 83391-3614

Fax: +49 (351) 83391-3300

E-Mail: markus.forytta@iws.fraunhofer.de

Fraunhofer-Institut für Werkstoff- und Strahltechnik

Telefon: +49 (351) 83391-3252

E-Mail: info@iws.fraunhofer.de

![]()