RIFTEK’s range of rail transport gauging systems are used in more than 60 countries world-wide and are characterised by their compactness, durability, portability and reliable use in particularly harsh environments. Most instruments can be used in-situ with no need for wheel-set removal and with battery powered devices offering up to 1000 measurements between recharge.

The comprehensive range includes the IDK series wheel diameter gauge for rolling circle measurement between 600 mm to 1300 mm using the ‘three points’ technique with a resolution to within 0.01 mm – made directly on the rolling stock without wheel set roll-out. The IDK-BT option features a Bluetooth interface for transfer of measured parameters directly to an optional PDA or for a PC based wheel set wear database management system. More compact versions are also available for smaller tramway wheels and for measurement in areas with restricted space.

RIFTEK’s IKP-5 series wheel profile gauges are available for standard wheels or as shortened and super-short versions for tramway wheels. With Bluetooth, PC software and an optional operator PDA the IKP-5 offers setting of measured and calculated wheel flange parameters including flange height, thickness and slope, wear parameters, angular profile parameters and more. Data is easily synchronised to external PC storage for wheel sets wear data processing and analysis.

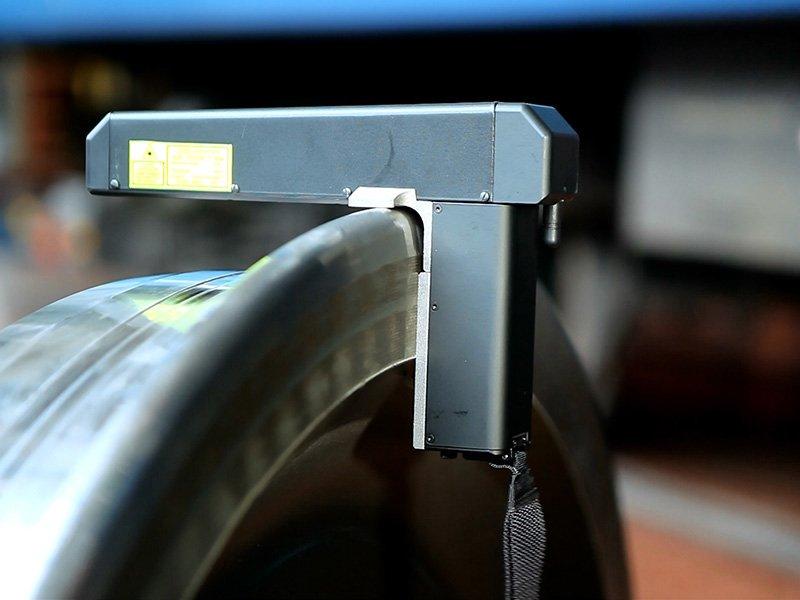

Similar operational features are available for rail track profile measurement with the PRP series profilometer. Its laser measurement head is mounted on an adjustable frame (with optional motorised linear translation) for full profile scanning results and graphical image visualisation of the combined actual and ‘as new’ cross sections displayed and recorded for further analysis.

Other products include the IMR series back-to-back distance gauge for measurement of railway, metro and tram wheels distances without wheel set roll-out. The IMR-series is a more compact tool for back-to back wheel distance measurement featuring a single laser scanning head. RIFTEK also supply various rail vehicle disc brake measurement devices that feature non-contact laser sensors and scanning heads.

For contactless automatic real-time measurement of wheel set geometrical parameters, RIFTEK’s 3DWheel series employs a combination of 2D laser scanners mounted on the side of the track that are calibrated into a common coordinate system. As the laser sensor detects a wheel passing through, the measurement cycle records the wheel profile in several sections with the results transferred through Ethernet to a control computer for profile reconstruction, dimensional calculation and wheel-set wear evaluation. The same 2D scanner can also be utilised for rail-head scanning for wear and correlation.

Ixthus Instrumentation are on hand to assist users for the operation and training for all RIFTEK rail transport gauging systems and other specialised optoelectronic measurement instruments. The Northamptonshire based instrumentation specialist, through its other selected distribution partnerships, supplies and support a wide range of sensors, transducers and complete systems for the measurement of displacement, force, torque and vibration. For further information please call +44 (0) 1327 353437, email info@ixthus.co.uk or visit www.ixthus.co.uk.

Ixthus works closely with leading global suppliers of non-contact sensing technologies as well as force, torque and vibration sensor and transducer manufacturers, providing a complete service with its knowledgeable technical staff available to solve customers‘ measurement problems – from the first enquiry to complete after-sales support.

Ixthus Instrumentation Limited

The Stables, Williams‘ Barn, Tiffield Road

NN12 6HP Towcester Northamptonshire

Telefon: +44 (1327) 353437

Telefax: +44 (1327) 353564

http://www.ixthus.co.uk

Telefon: +44 (1327) 353437

E-Mail: graham.pattison@ixthus.co.uk

MEPAX

Telefon: +44 (7748) 815-825

E-Mail: e.palmer@mepax.com

![]()