Material in more than 20 different versions

For the materials usage in mountainous terrain, special requirements on the material quality of the components applied. These included, in particular, maximum weather resistance as well as highest structural and strain safety. On the basis of these requirements, thyssenkrupp Schulte drew up a precisely tailored parts list and provided customized steel sheets, bars and tubes. The delivery included materials in a total of more than 20 different designs – up to 12,000 millimeters long and 20 millimeters thick.

For optimum corrosion protection, the materials were further processed by project partner ZÜBLIN. The finished parts were eventually flown by helicopter from the foot of the Zugspitze in Grainau, near Garmisch-Partenkirchen, to one of the highest construction sites in Germany. At its destination at an altitude of about 1,000 metres, each of the steel parts is now successfully used in the arch bridge and serves as a girder, web plate, pillar or handrail. With the material used, up to 100,000 hikers will be able to cross the unique Höllentalklamm safely from the start of the season.

Detlef Schotten, Managing Director of thyssenkrupp Schulte, is glad about the good cooperation with all project partners and the successful completion: "When the DAV Garmisch approached us, we did not hesitate to get involved with a sponsorship and to contribute our material know-how to the joint success of all service providers involved in the project.”

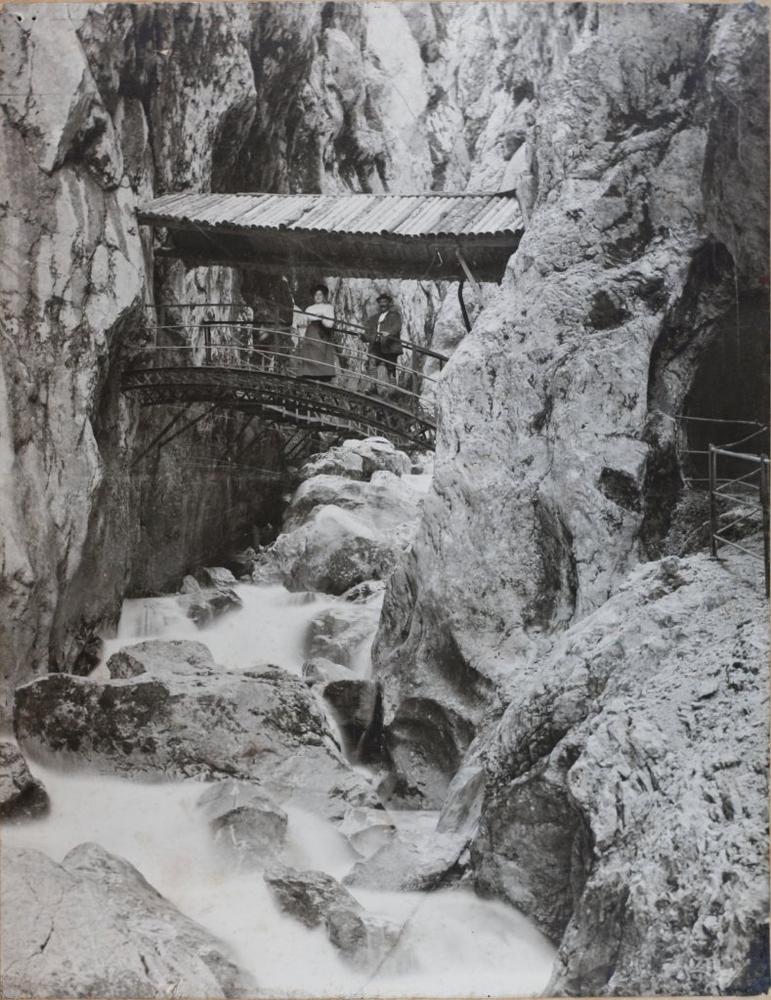

Historical bridge as a symbol of engineering art and pioneering spirit

The old arched bridge already had a long history. It was inaugurated more than 115 years ago and has since been a symbol of engineering and pioneering spirit. Every year it prepared the way to the Zugspitze for tens of thousands of hikers and offered spectacular views of the Höllentalklamm gorge. The new bridge, which has a span of 7 metres and two adjoining footbridges, is to follow this example and become a new landmark on the way to Zugspitze.

thyssenkrupp Schulte GmbH is the materials partner for steel, stainless steel and nonferrous metals. The company provides tailor-made services for more than 70,000 customers from industry, trade and construction. The basis for this is a wide range of flat products, sections and tubes for all requirements and tailored to the individual wishes of customers. Another decisive competitive advantage is customer proximity. With over 40 locations, thyssenkrupp Schulte is always close to its customers and can deliver quickly and reliably anywhere in Germany. The diverse product range, competent technical advice and comprehensive services round off the portfolio of Germany’s largest materials dealer.

With around 480 locations – 271 of them warehousing locations – in over 40 countries, thyssenkrupp Materials Services is the biggest materials distributor & service provider in the western world. The wide-ranging capabilities offered by the materials experts enable customers to concentrate more on their individual core business and span two strategic areas: global materials distribution as a one-stop-shop – from steel, tubes and pipes, nonferrous metals and specialty materials to plastics and raw materials – and tailored services in the areas of materials management and supply chain management. An extensive omnichannel architecture offers 250,000 customers worldwide round-the-clock access to more than 150,000 products and services. A high-performance logistics system ensures that all deliveries are integrated smoothly into customer production processes on a just-in-time or just-in-sequence basis.

thyssenkrupp Materials Services GmbH

thyssenkrupp Allee 1

45143 Essen

Telefon: +49 (201) 844-0

http://www.thyssenkrupp-materials-services.com/de

Head of External & Internal Communications

Telefon: +49 (201) 844-534416

E-Mail: lars.bank@thyssenkrupp.com

External and Internal Communications

Telefon: +49 (201) 844-553266

E-Mail: johanna.floeter@thyssenkrupp.com

![]()